Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]

Click here for more about our skid steer breakerYou can replace the breaker rod with the post driver rod.Technical DetailsOperating weight550 lbsWorking pressure210 psiWorking flow 9.5-16 GPM (36-60 L/min)Impact rate500-900 BPMImpact energy600 jouleC

Secure Shopping

100% Safe Guarantee

Free Shipping

On orders over $30

Money-Back

30-Day Guarantee

Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]

Click here for more about our skid steer breaker

You can replace the breaker rod with the post driver rod.

Technical Details

| Operating weight | 550 lbs |

| Working pressure |

210 psi |

| Working flow | 9.5-16 GPM (36-60 L/min) |

| Impact rate | 500-900 BPM |

| Impact energy | 600 joule |

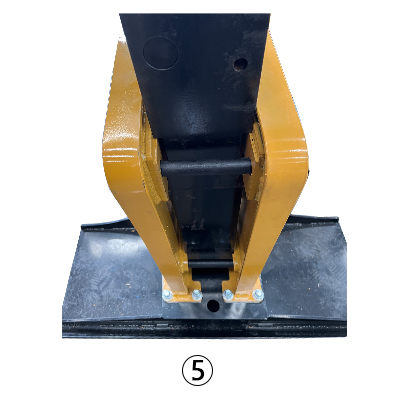

| Chisel diameter | 2.7" (68mm) |

| Hydraulic hose diameter | 1/2" |

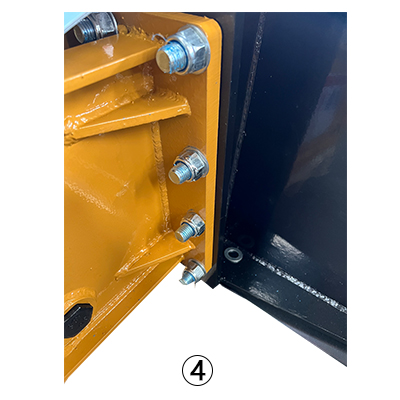

| Ear spacing - inside | 10.2" (258mm) |

| Ear spacing - outside | 11.4" (290mm) |

| Pin center to center | 8.8" (224mm) |

| Package Dimensions | 50.39" × 24.01" × 23.62" |

| Shipping weight | 870.82 lbs |

Description

The Skid Steer Concrete Breaker, featuring a 2.7" chisel, is perfect for tasks that require both light and medium effort, making it popular among demolishers, landscapers, and those working on construction sites.

With the striking power of up to 400-900 Blows Per Minute.

Solutions to common problems

The hammer is not working after the installation

-

Improper bushing replacement. Refit the inner bushing. Make sure to use the original.

-

Quick couplers are installed wrong. Check connectors and replace them as needed.

-

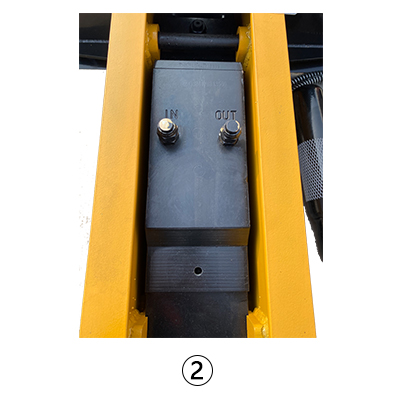

Supply hoses have been reversed. The pressure line from the pump must be connected to the port marked IN. The return line connects to the port marked OUT.

-

Nitrogen pressure is too high, Release nitrogen and recharge as needed.

Why does the hydraulic hammer suddenly stop hammering?

-

The backhead pressure is too high. Release nitrogen and recharge as specified.

-

The backhead is filled with oil. Disassemble the back head and replace the seal.

-

The control valve is stuck. Disassemble and clean the valve, and replace the worn valve.

-

Oil flow is not sufficient. Repair the pump, and adjust the hammer valve.

Nitrogen Pressure

Details

Includes

What Our Customers Say

Absolutely no complaints!

A purchase I am deeply proud to own.

- Wystan P..

Absolutely no complaints!

It’s a very well made and a very, very useful device.

- Teyrnon D..

Absolutely no complaints!

I am very, very, very, very satisfied with it.

- Beli S..

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/products/AGT-Industrail-AGT-SSHH-680A-Skid-Steer-680-Hydraulic-Concrete-Breaker-Attachment-3.jpg?v=1655955861)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/products/AGT-Industrail-AGT-SSHH-680A-Skid-Steer-680-Hydraulic-Concrete-Breaker-Attachment.jpg?v=1655955861)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/products/AGT-Industrail-AGT-SSHH-680A-Skid-Steer-680-Hydraulic-Concrete-Breaker-Attachment-4.jpg?v=1655955861)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/products/AGT-Industrail-AGT-SSHH-680A-Skid-Steer-680-Hydraulic-Concrete-Breaker-Attachment-2.jpg?v=1655955861)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/products/AGT-Industrail-AGT-SSHH-680A-Skid-Steer-680-Hydraulic-Concrete-Breaker-Attachment-5.jpg?v=1652842567)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/files/s-l1600_15.webp?v=1750642808)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/files/s-l1600_16.webp?v=1750642808)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/files/s-l1600_17.webp?v=1750642808)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/files/s-l1600_19.webp?v=1750642808)

![Premium Select Agt Skid Steer 680 Hydraulic Concrete Breaker | Agt-sshh-680a Online Exclusive [YzkKHqPj]](https://cdn.shopify.com/s/files/1/0254/7924/9971/files/s-l1600_18.webp?v=1750642808)

![Jabsco Filterless Bilge/Sink/Shower Drain Pump - 4.2 GPM - 24V [50880-1100]](https://cdn.shopify.com/s/files/1/0925/7202/5119/files/96960XL.jpg?v=1748386159)