Electroweld industries is a leading manufacturer of resistance welding equipment, serving the industry for over 45 years. Our welding machines are designed to provide a production solution at an affordable price while ensuring reliability and low cost maintenance.

Electroweld Press Type Spot Welder 100KVA with Constant Current Controller (SP-100PRS-C)

-(Weldability Sheet Thickness (2 x mm): S.S/M.S Sheet- 1.0mm-6.0mm, 4-19 SWG, 4-19 AWG)

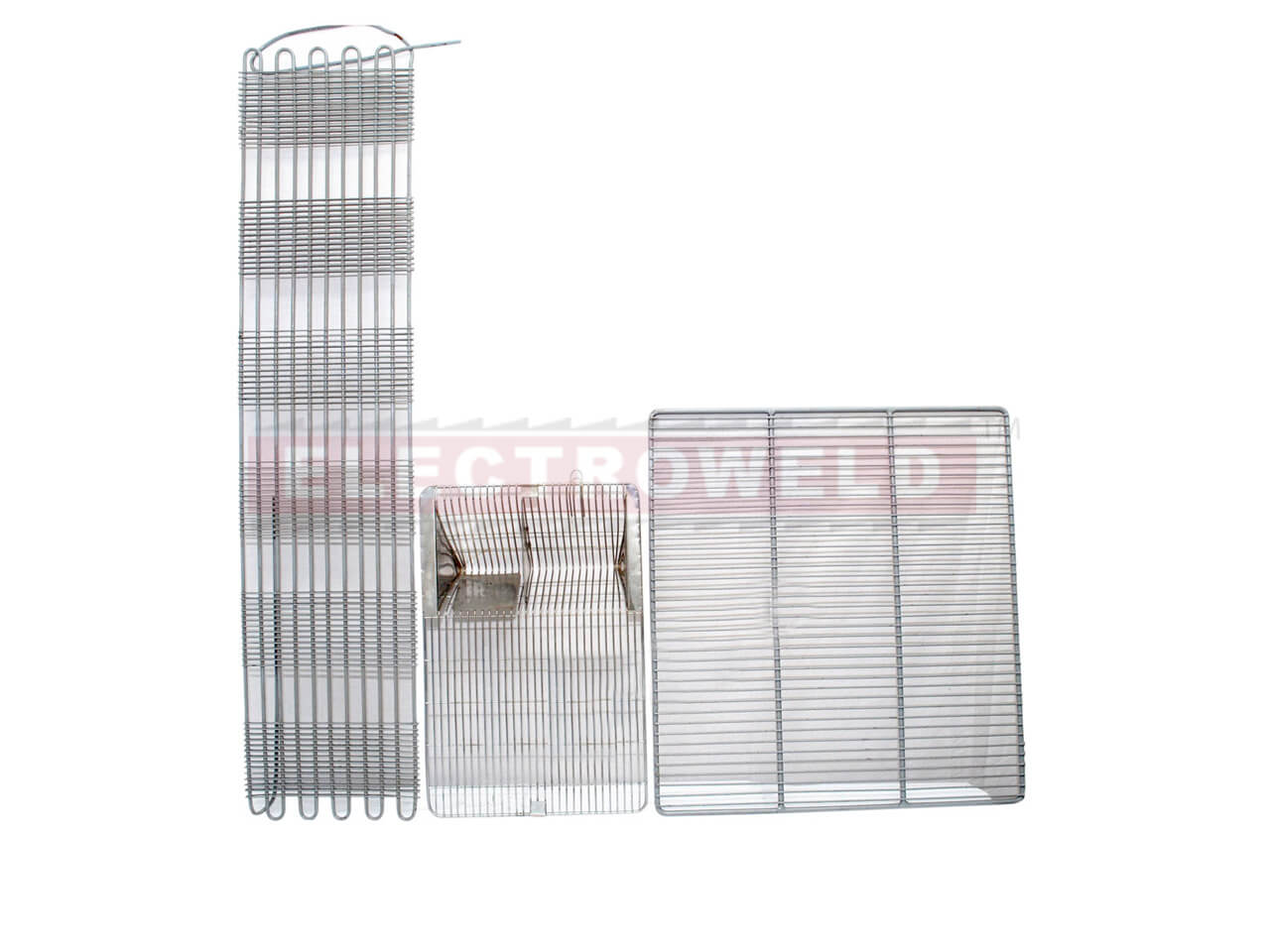

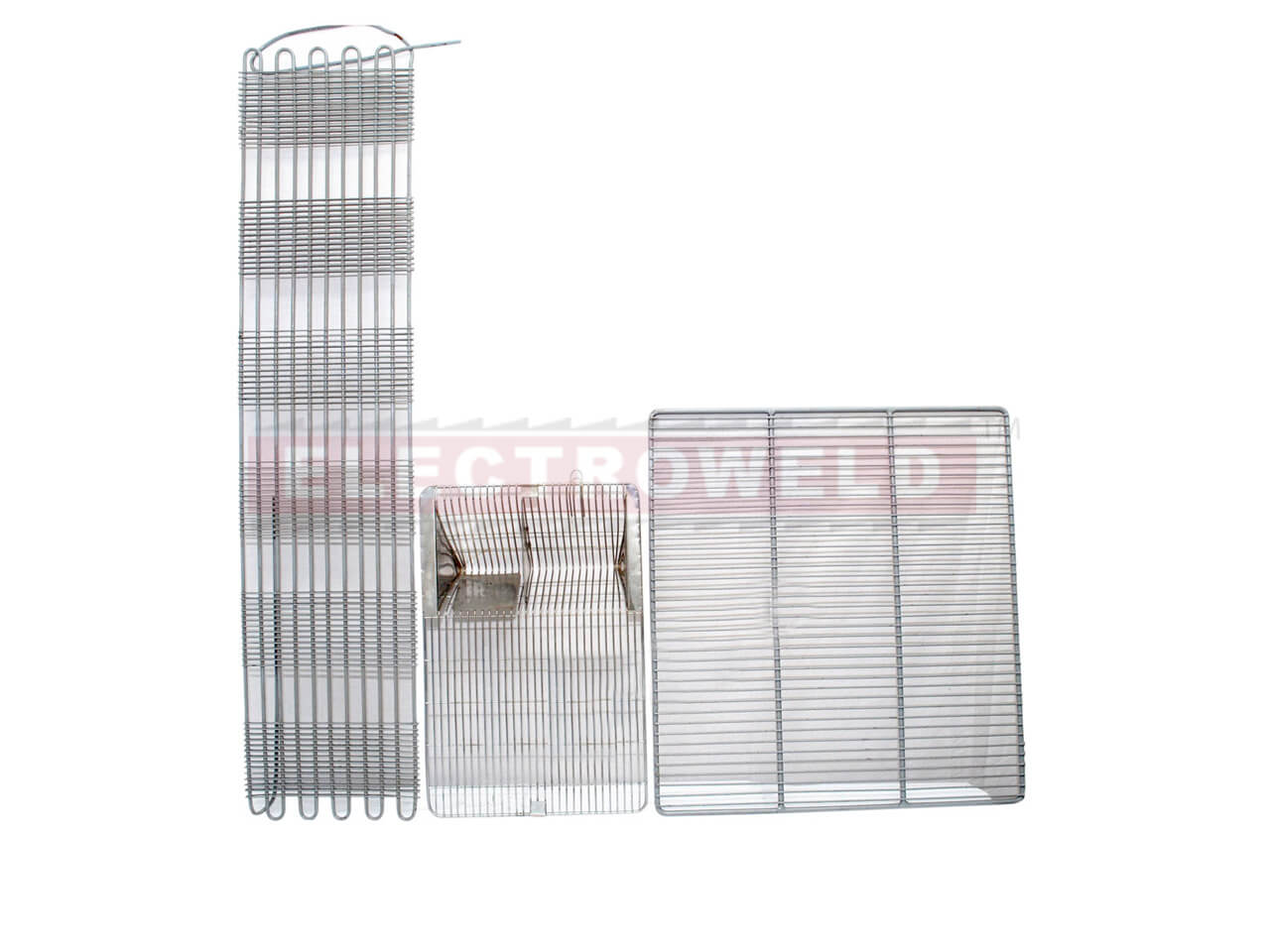

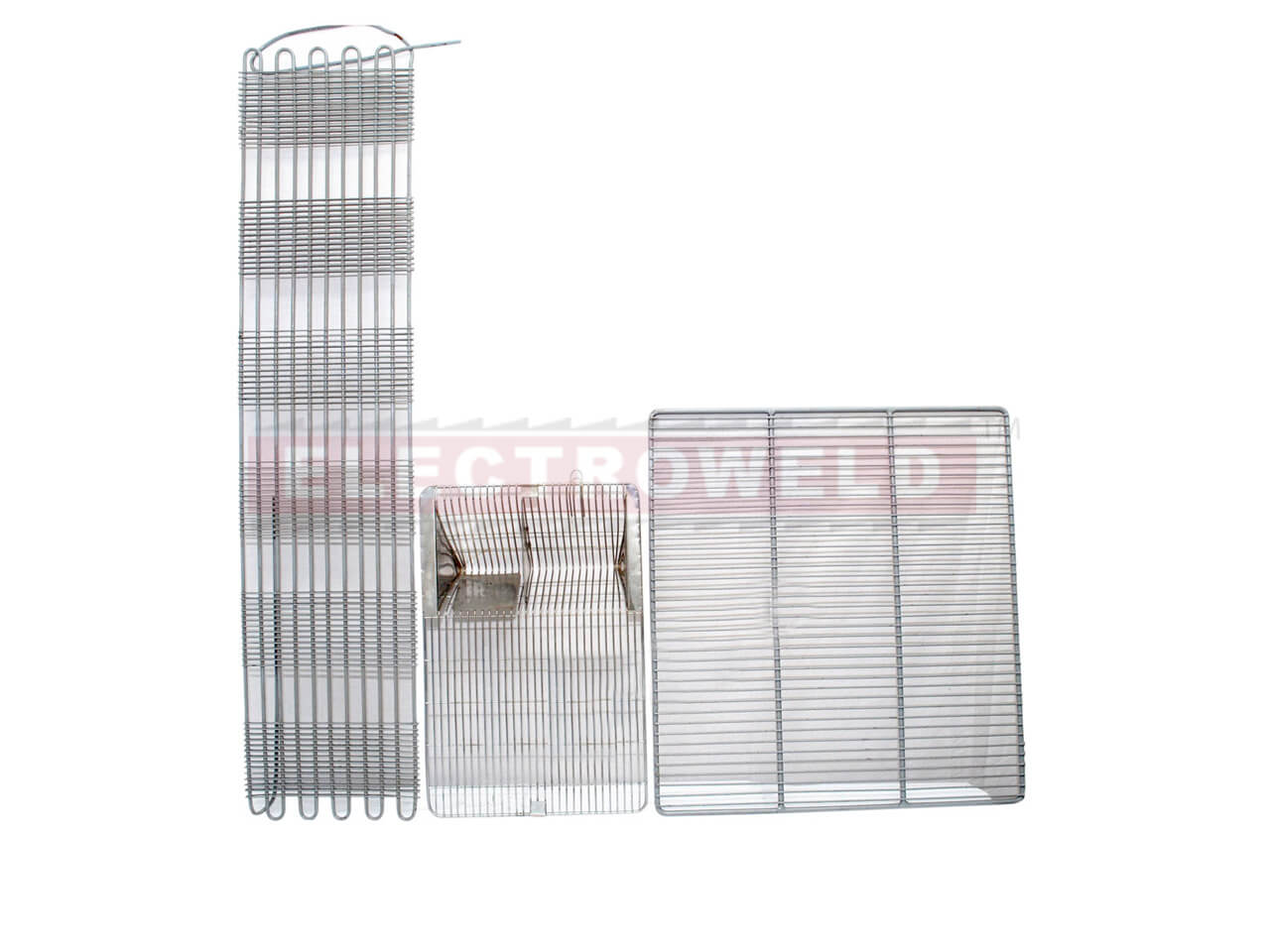

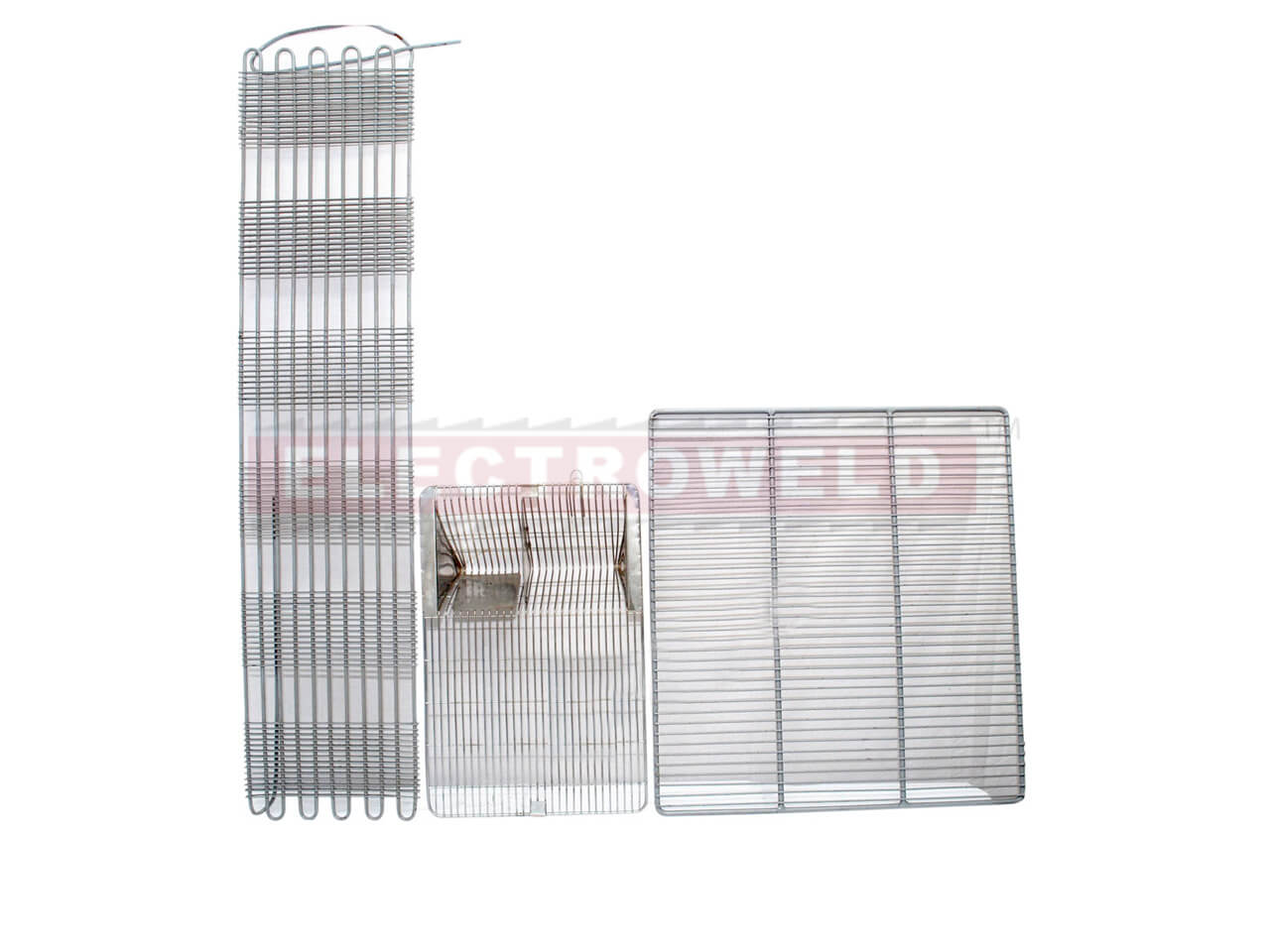

-(Weldability Cross Wire/Mesh Application-Wire Diameter (2 x mm): 2.0mm-12.0mm,Approx. double the weldability ranges indicated above)

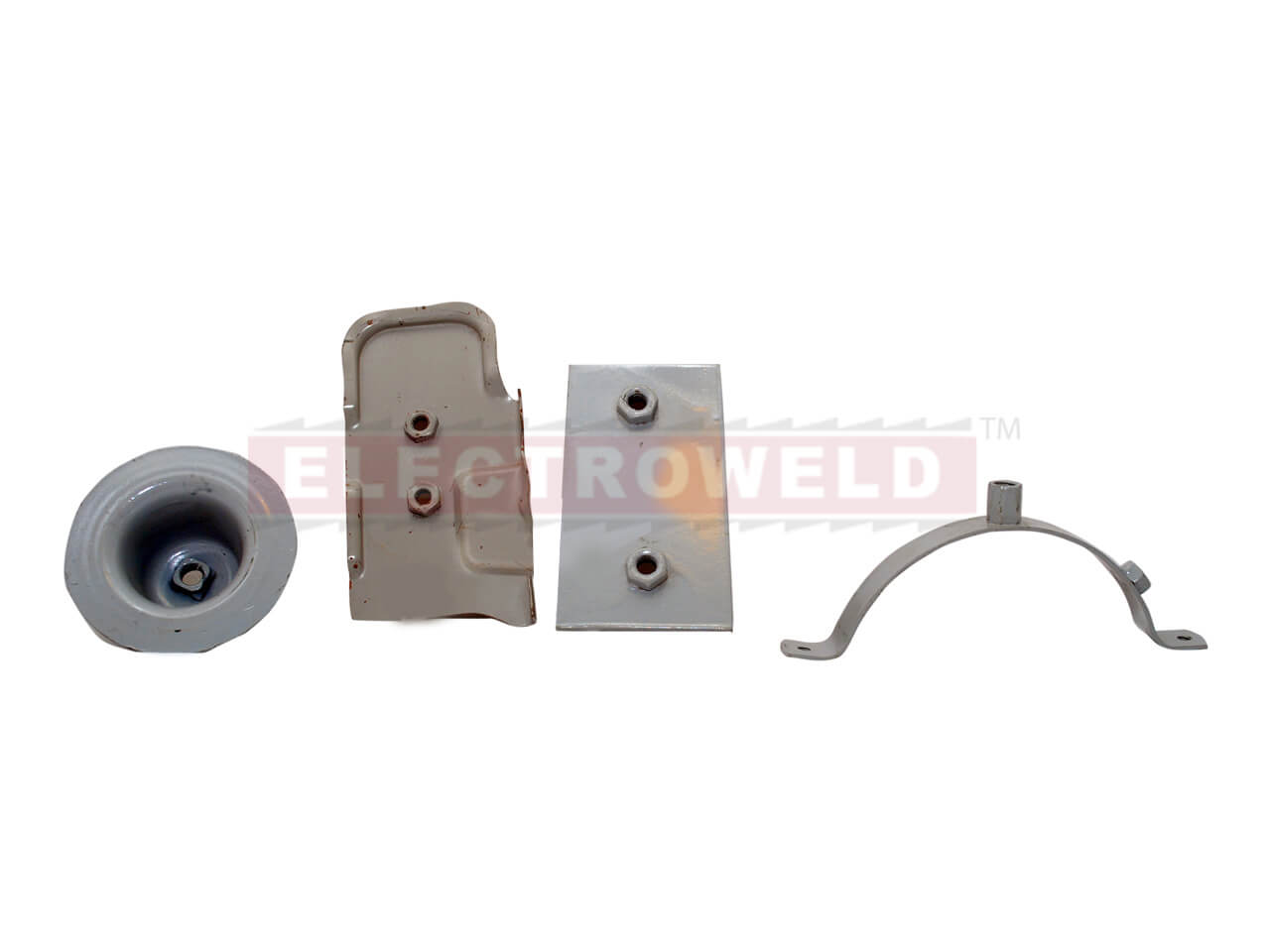

-(Weldability S.S/M.S Projection Weld Nut or Weld Bolt on S.S/M.S Sheet with Thickness-1mm-4mm: M10-M20)

Applications: Spot / Projection Welding, Electro-Brazing, Cross Wire Welding, Sheet Metal- 2-ply or Multi-ply, Mark-less Welding, Resistance Heating and Soldering. Capable of Welding Low Carbon Steel,High Carbon Steel,High Strength Steel,Nickel Alloy,High-Temp Alloy,Titanium. Confirmation of weldability of other materials can be provided on request.

Users Include: General engineering work-shops, makers of furniture, electrical instruments, containers, barrels and drums, telephone, radio communication devices, clocks, kitchenware, textile machinery and spares, automobiles, bicycles, motor-cycles, scooters, auto-ancillaries, toys, air-conditioners, refrigerators, transformers, motor, switch gear, etc.

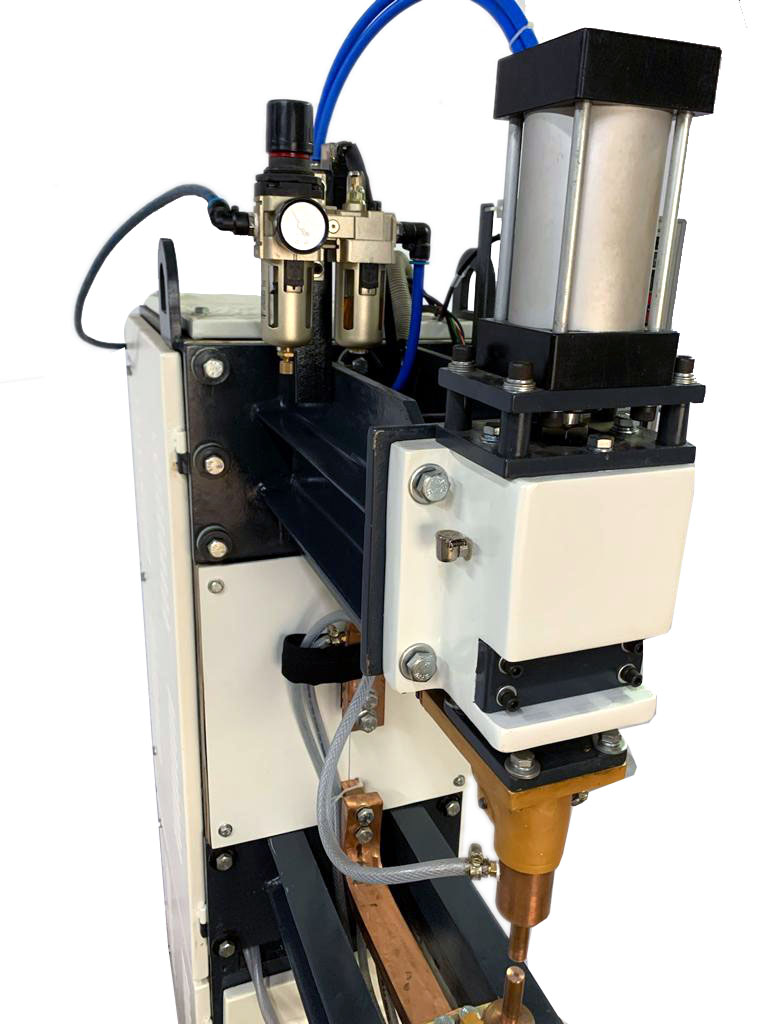

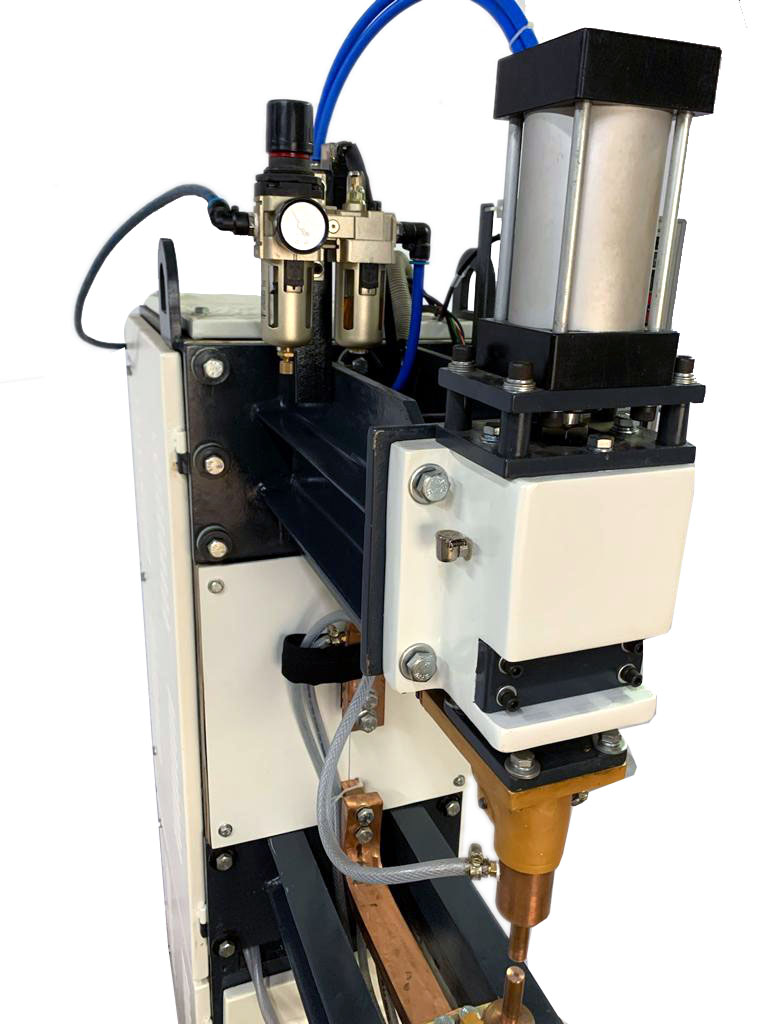

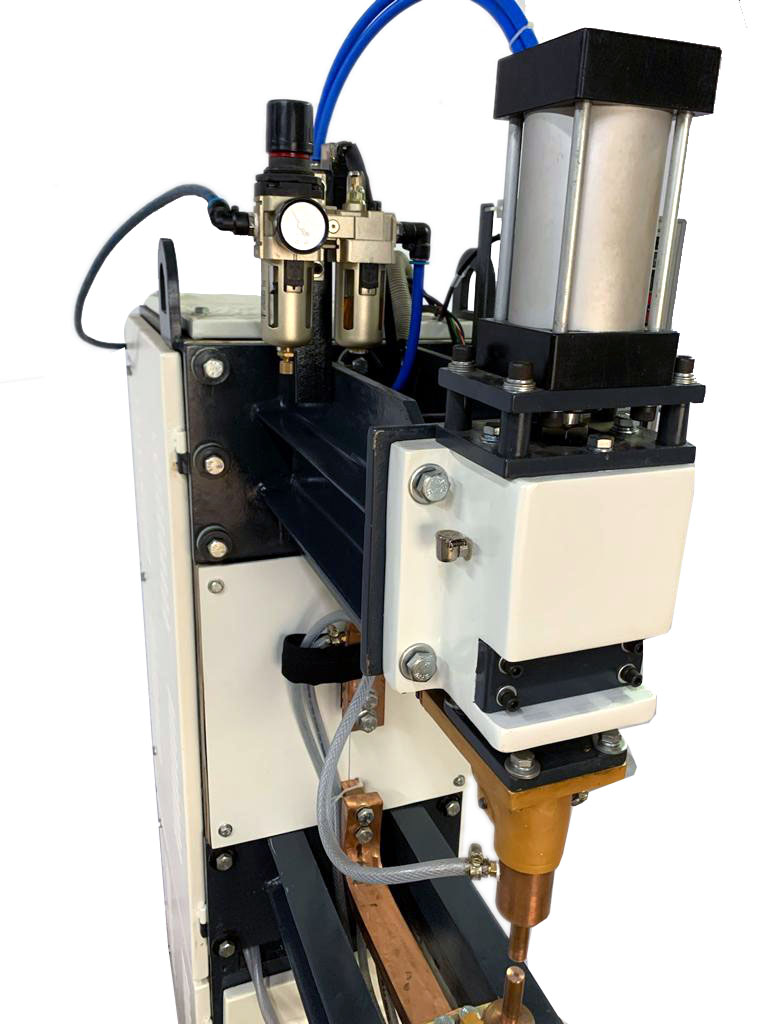

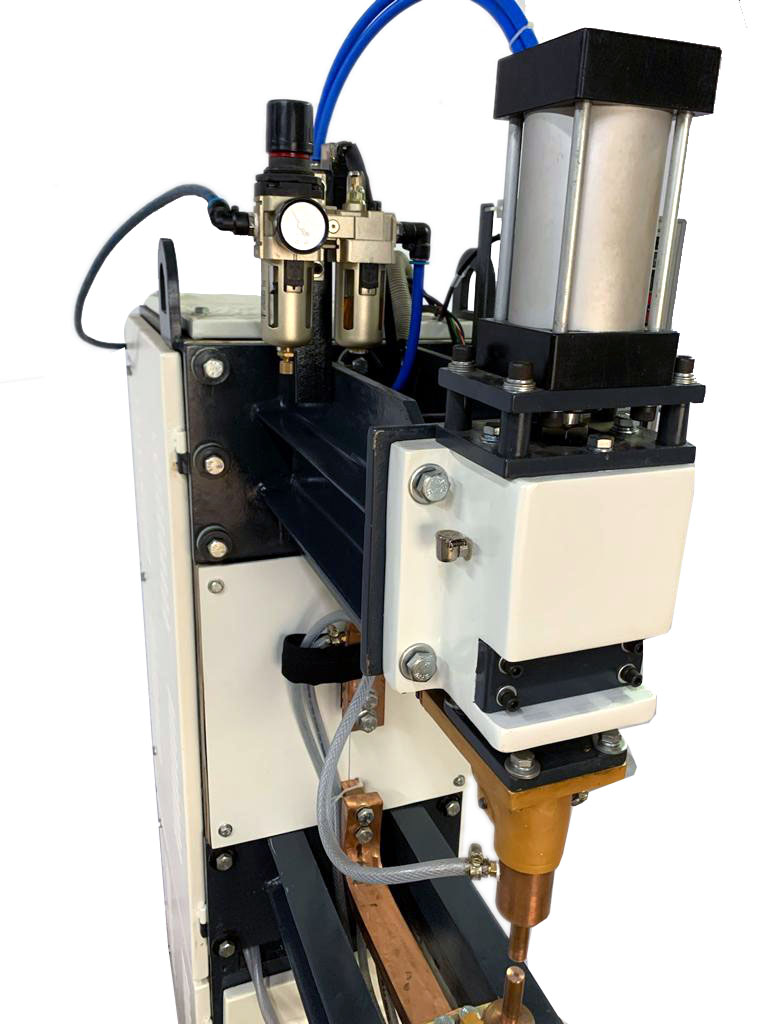

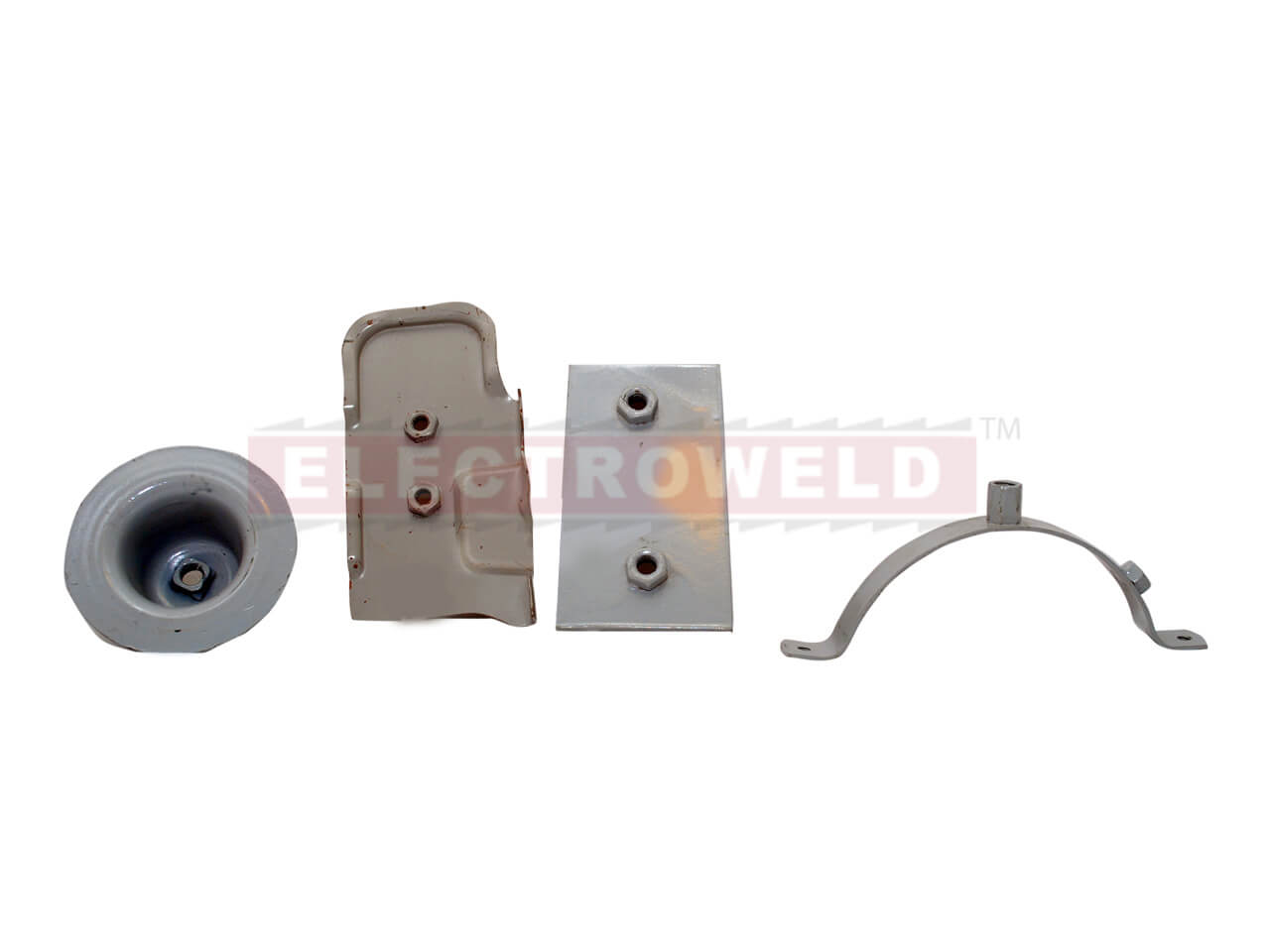

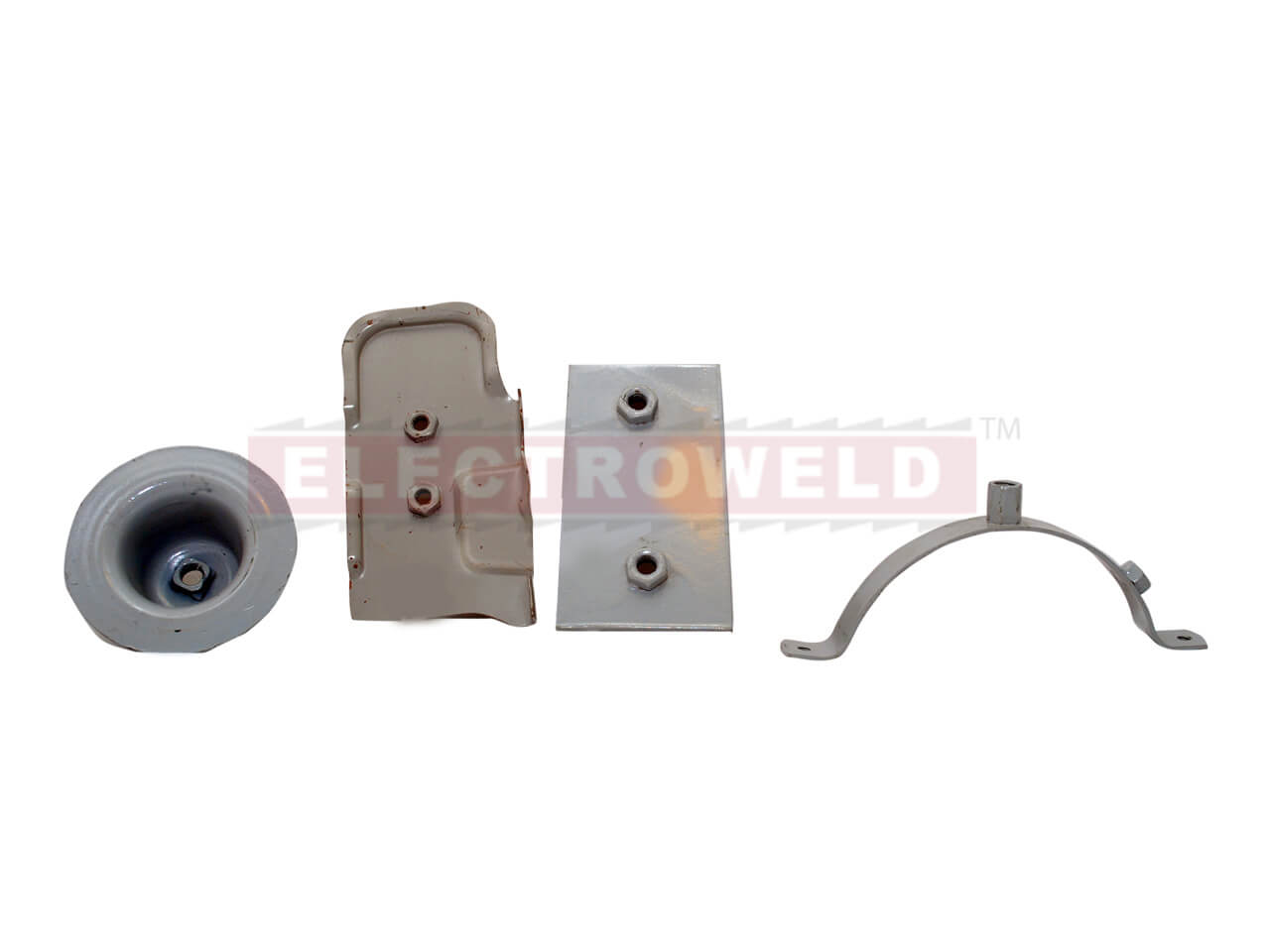

Construction : Heavily fabricated with streamlined appearance, suitably stiffened at points of stress. The transformer is mounted directly on to the body and the bearings for the arm are provided in the same.

Cooling System: Electrodes, Electrode holders secondary water cooled, water required to be free from residue forming impurities and at a temperature of less than 30* C or 85* F. If water temperature is higher, increased water flow is required.

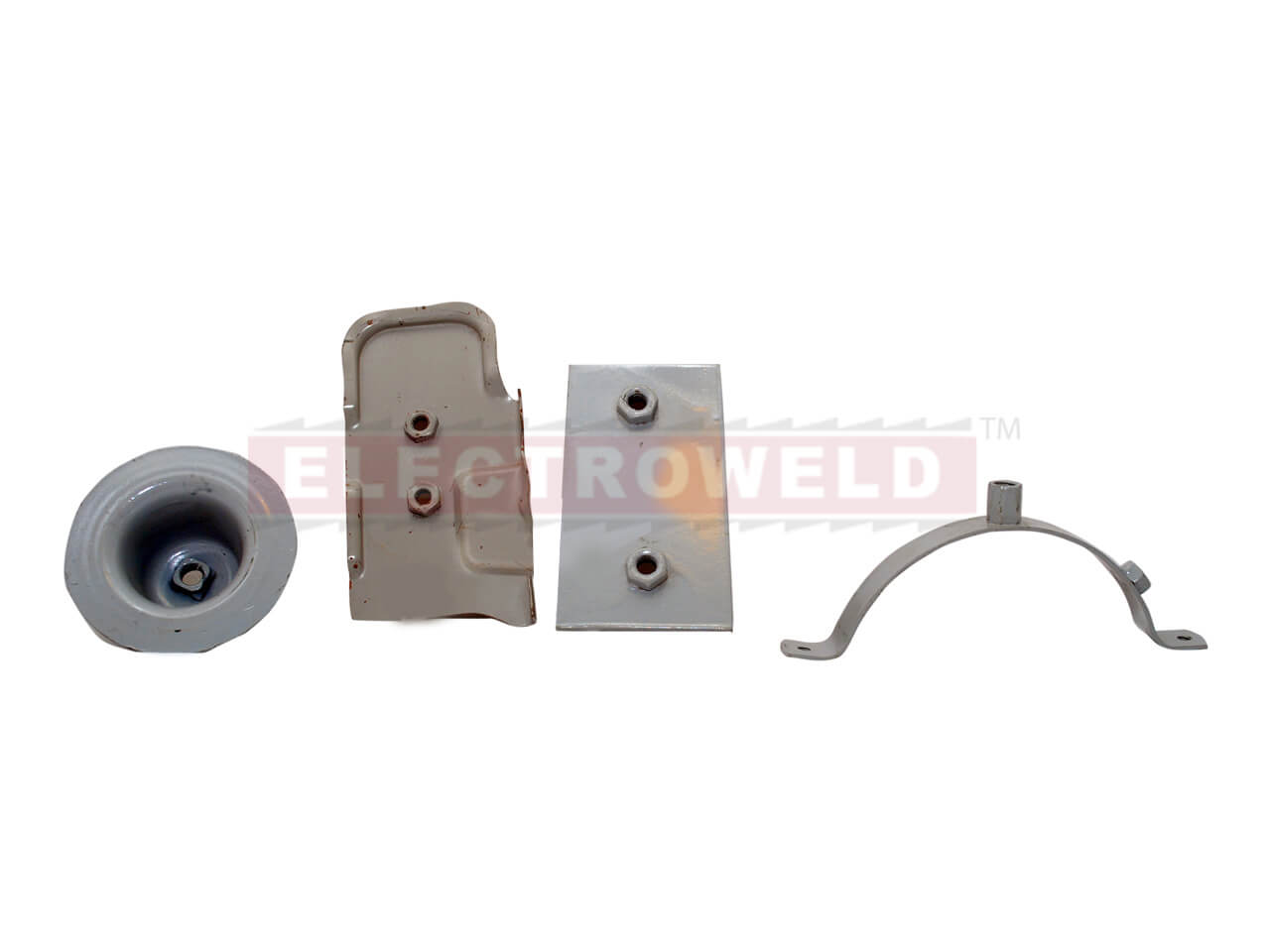

Electrodes: One pair Morse Taper II straight electrodes supplied as standard with the machine, Other types available on request.

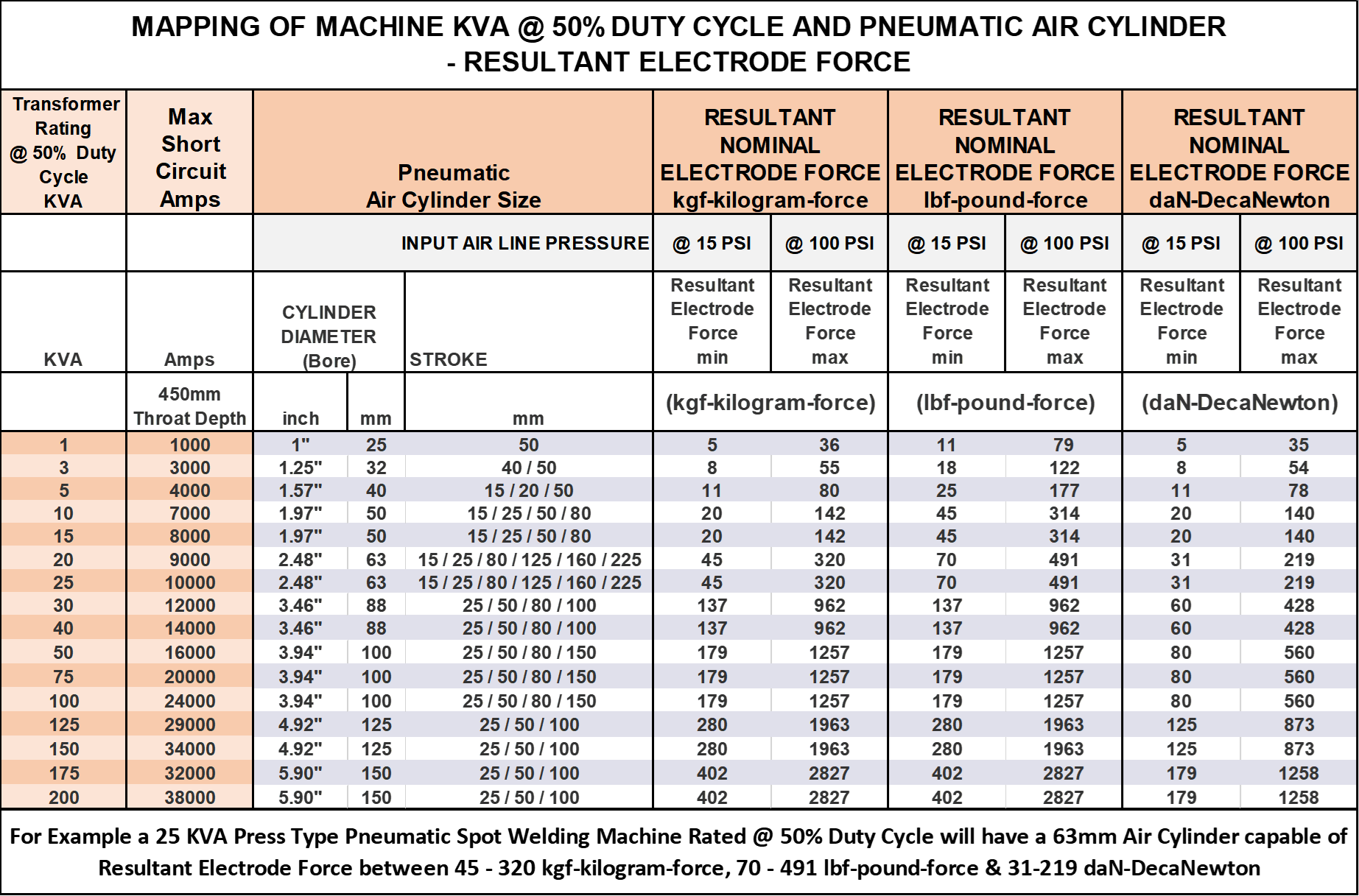

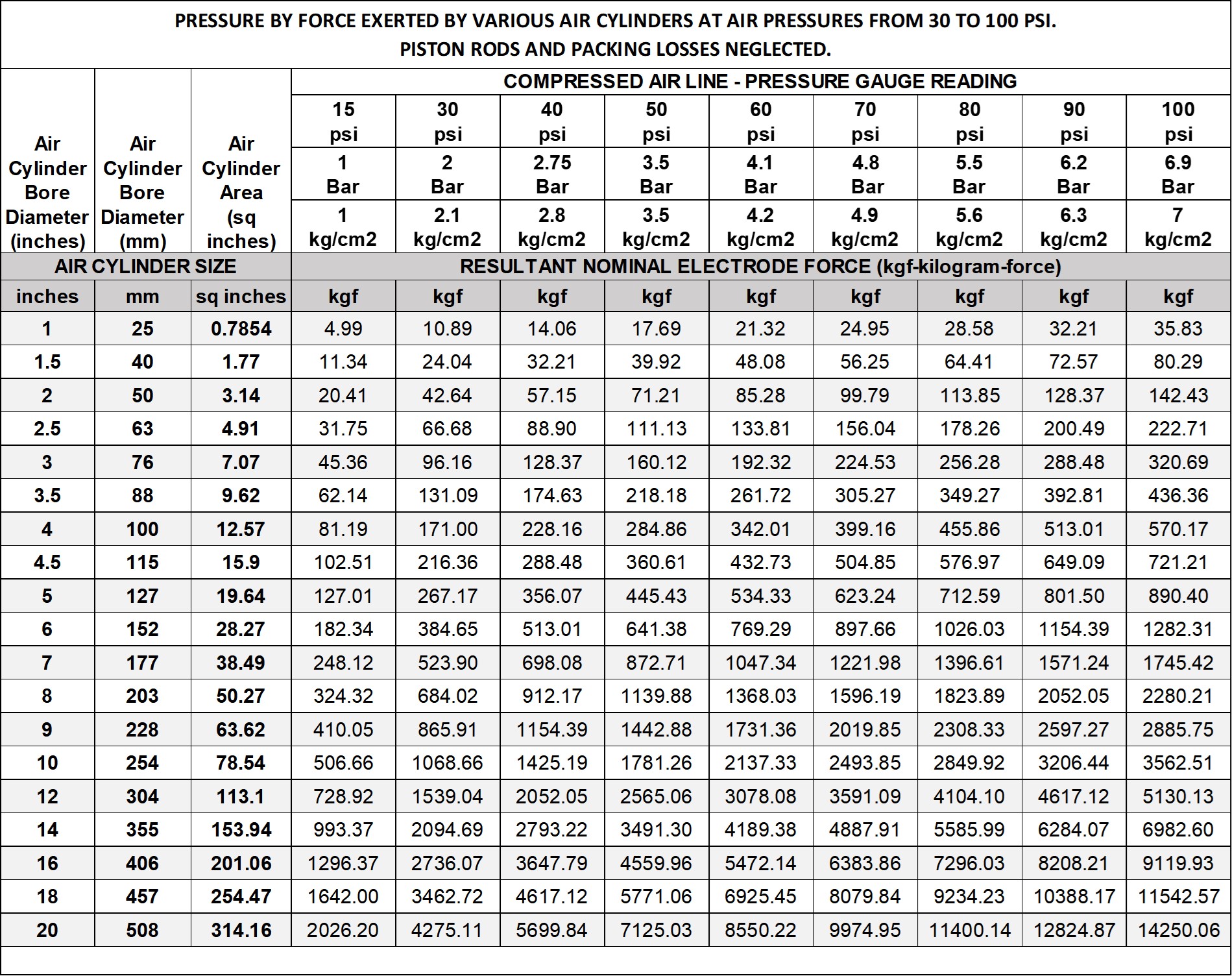

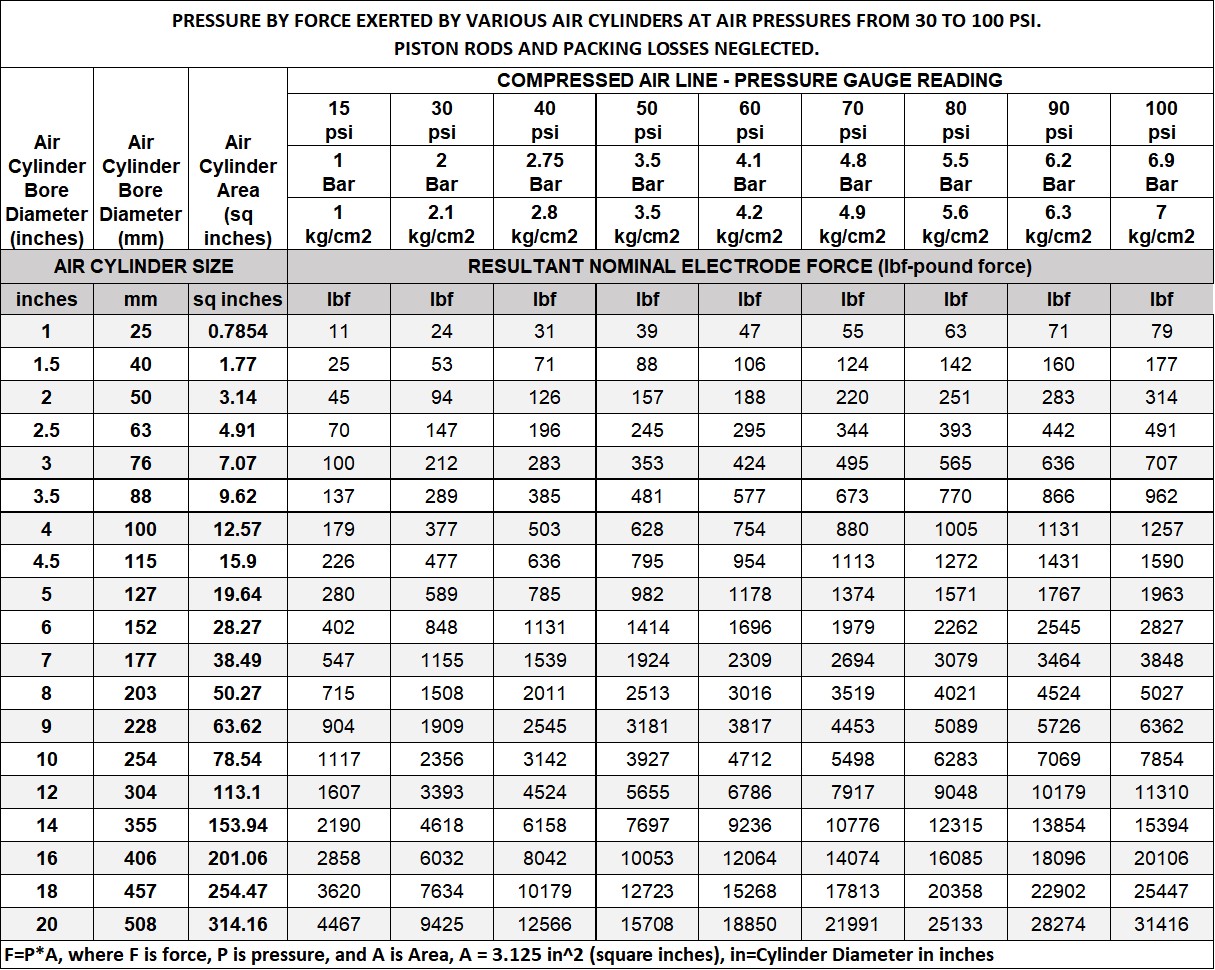

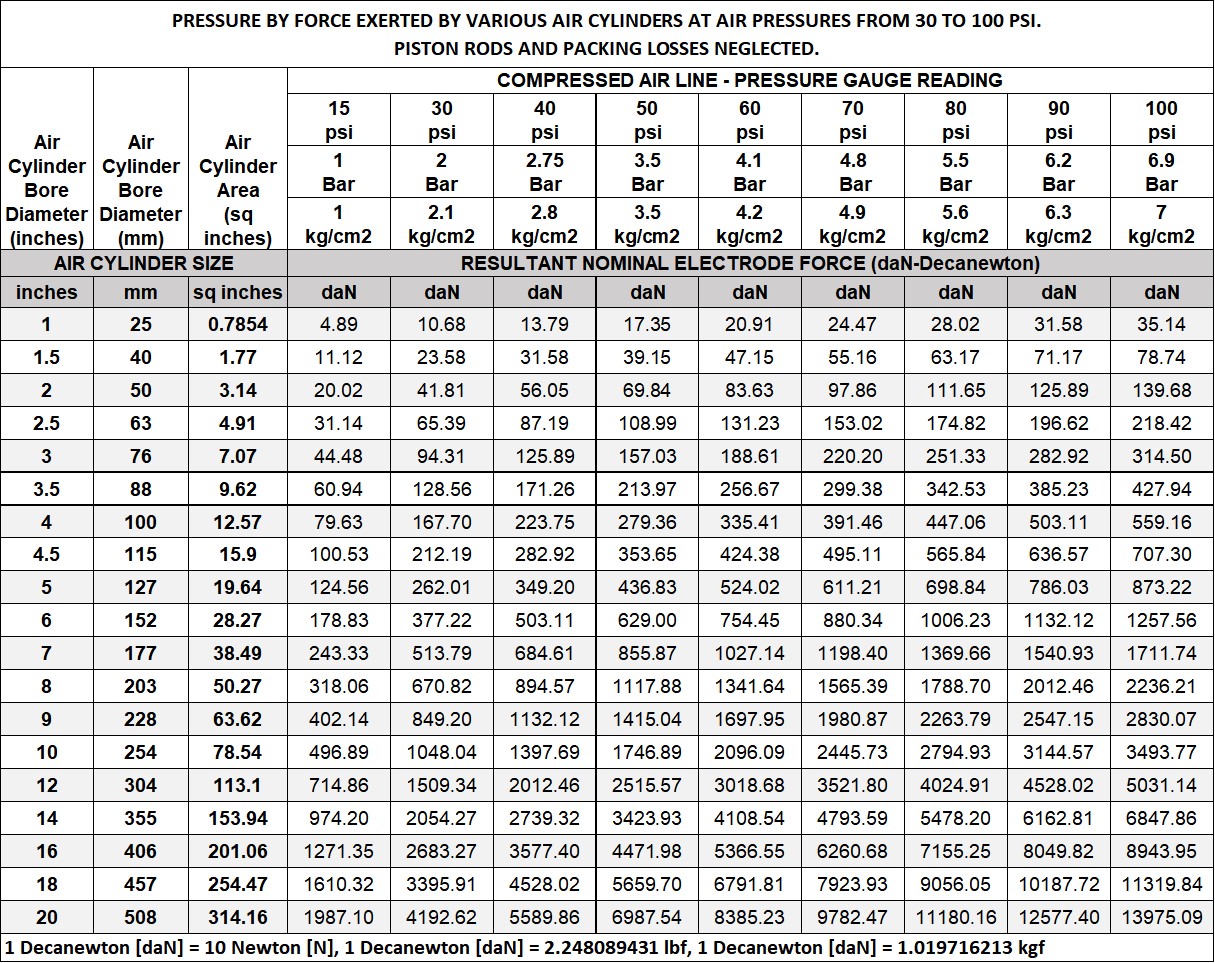

Adjustment of Electrode Force : By means of Air Pressure. The electrode force is adjustable adjusted via the Regulating Valve which controls the compressed line air pressure going into the Pneumatic Air Cylinders.

Adjustment of Electrode Stroke: By vertical adjustment of electrode holder.

Standard Pneumatic Air Cylinders: Configurable with 2 positions- extended (welding position) and retracted (part loading position)

Optional Fixed Retractable Pneumatic Air Cylinder:

Configurable with 3 positions:

1. Retracted Load position: In the Load position, the electrodes are as far apart as they can be. This fully open position allows an operator to load large parts in between the electrodes.

2. Weld Ready position: In the Weld Ready position the electrodes are retracted partly. This allows the operator to cycle the welder more quickly, without the electrodes returning their full stroke every weld cycle.

3. Weld position - Fully Extended (welding position) to the maximum stroke of the cylinder

Optional Adjustable Retractable Pneumatic Air Cylinder(dual stroke): Provides the same 3 positions-a retracted position (All the way open), another middle weld ready position (a smaller gap but tips not touching) and then a weld position (tips touching). Additionally the operating weld stroke (distance between the electrode tips when welding) can be adjusted from zero to the maximum stroke of the cylinder. With an adjustable retractable stroke weld cylinder, this Weld Ready position is adjustable. With a fixed retract cylinder, the distance traveled between the Load and the Weld Ready positions is always the same and can not be adjusted.

Current Control: By means of fine setting through controller

Weld Initiation: By means of Foot Switch which initiates the weld only after preset pressure is built up.

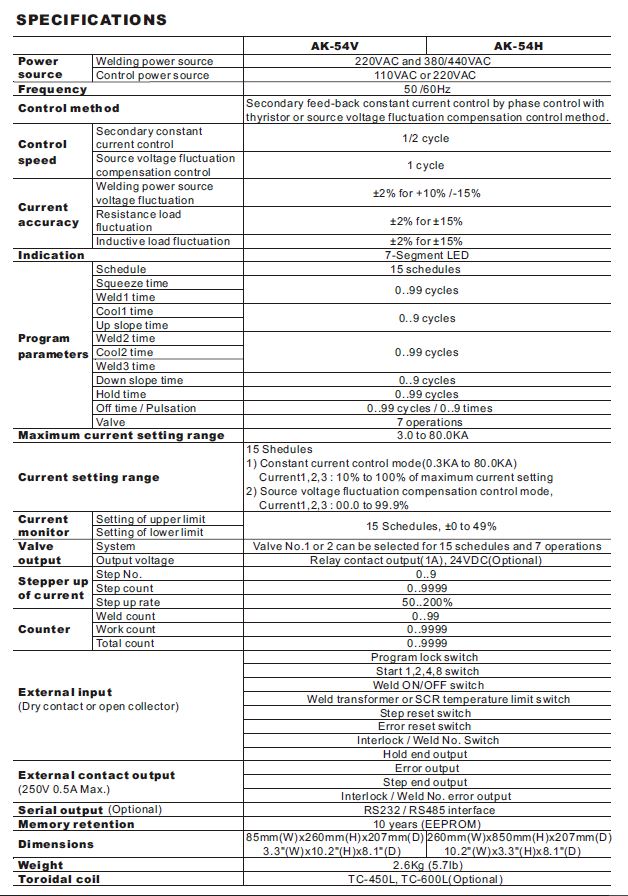

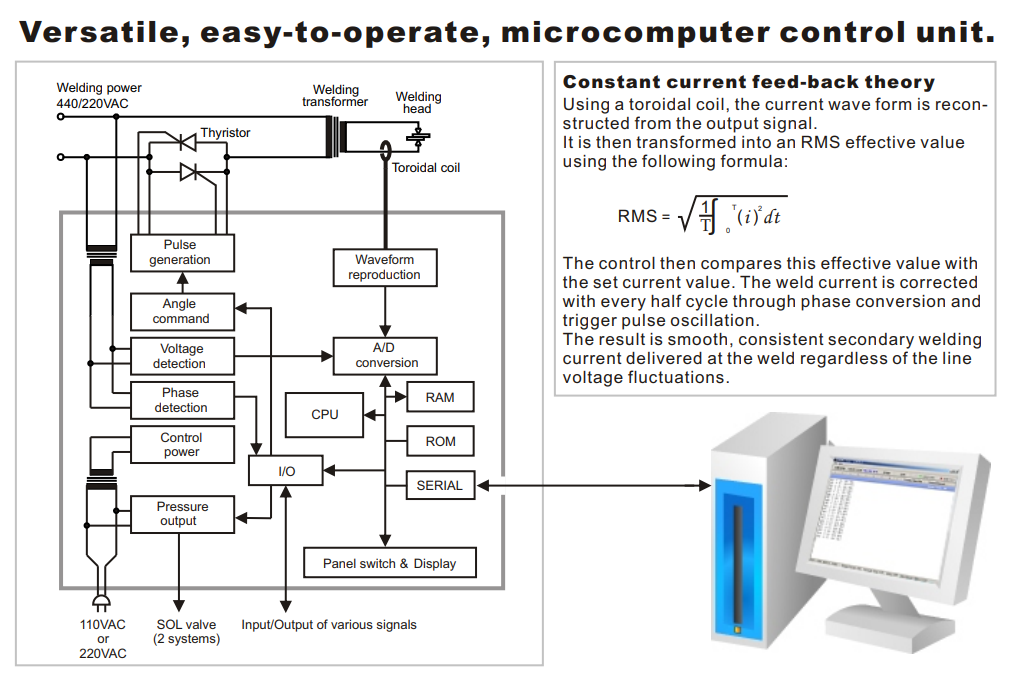

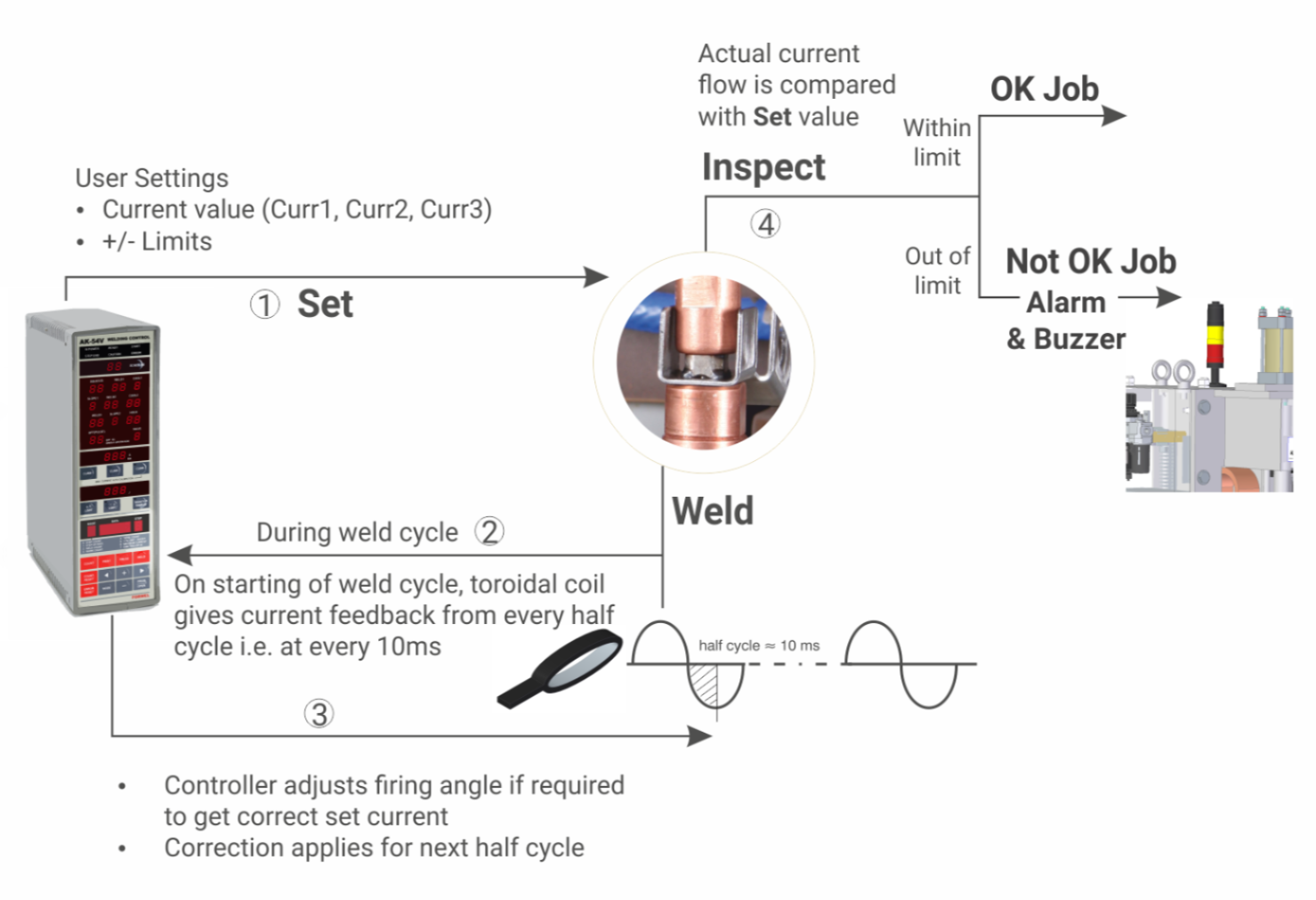

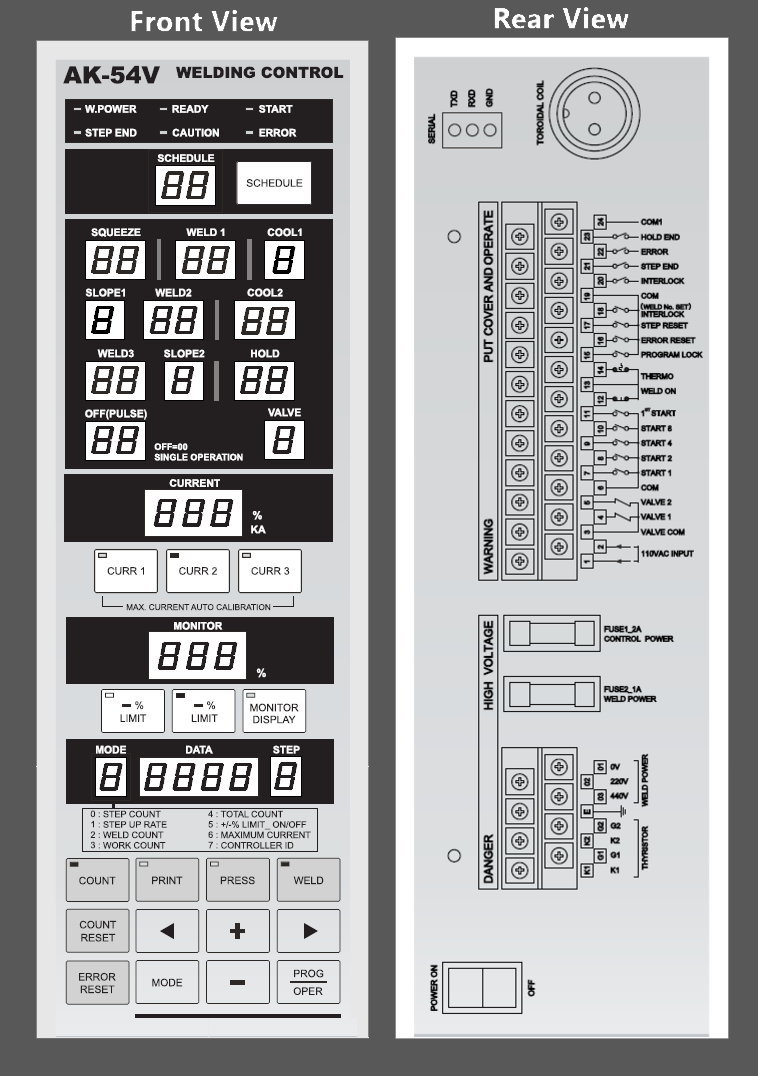

Electronic Control: Electroweld Forwel Constant Current Controller AK-54.

The controller supplies stable welding current by secondary feed-back constant current method. Thus maintaining the current as per ‘Set Value’ throughout the welding process.Using a toroidal coil, the current wave form is reconstructed from the output signal. It is then transformed into an RMS effective value. The controller then compares this effective value with the set current value. The weld current is corrected with every half cycle through phase conversion and trigger pulse oscillation. The result is a smooth, consistent secondary welding current delivered at the weld regardless ofthe line voltage fluctuations.

Features:

- 100% certainty of welded spots

- non-confirmating spots can be alarmed instantly

- supplies stable welding current by secondary constant current method

- networking of upto 32 machines (Optional)

- data acquisition software (Optional)

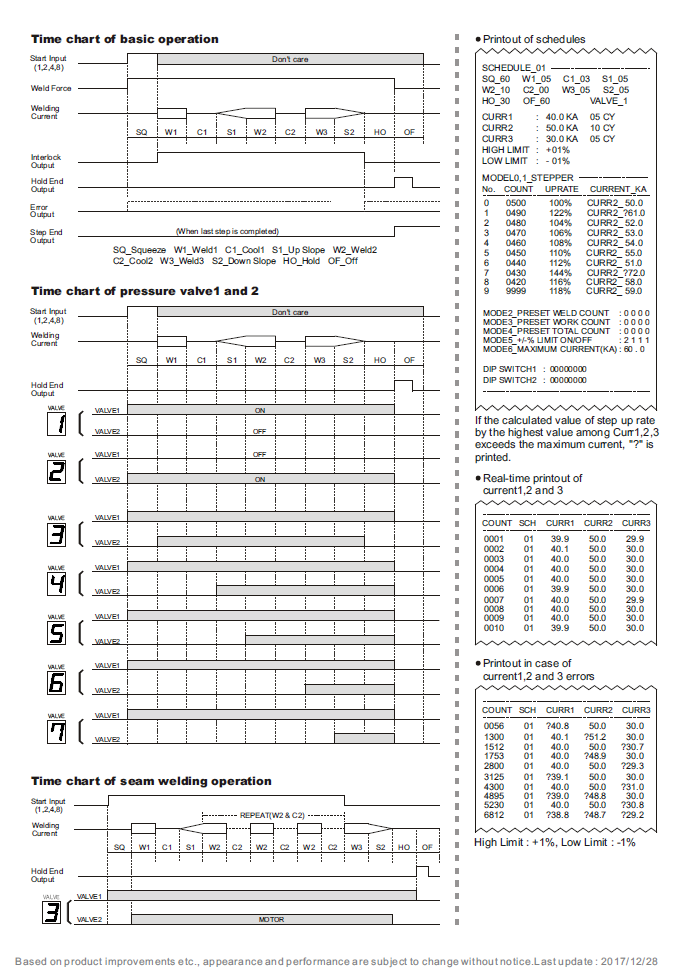

- printouts of welding schedues, real time and of errors(Optional)

- no need of backup battery as it stores all data to EEPROM

- 15 multiple weld schedules can be called while welding

- different thickness parts can be welded in the same welding sequence by calling multiple schedules

- 3 impulse weld schedules

- 9 steppers / linear stepper

- up and down Slope

- 2 Pressure valve output and 7 operations

- current 1,2,3 monitor with high/low monitor

- 3 easy to operate counters to aid in systematic quality control and tip dressing schedules

Constant Current Controller-Benefits for Nut Projection Welding:

1. The welded nut withstands 2 times breaking torque than that of standard specification

2. No Retapping

3. No Co2 Tagging

4. Minimizes Rework, Reduces Cost

5. Avoids frequent Destruction Testing

6. No adverse effects on the Threads and thus responds to go-no go test positively

*Weldable Materials-Low Carbon Steel,High Carbon Steel,High Strength Steel,Nickel Alloy,High-Temp Alloy,Titanium,Bronze,Brass

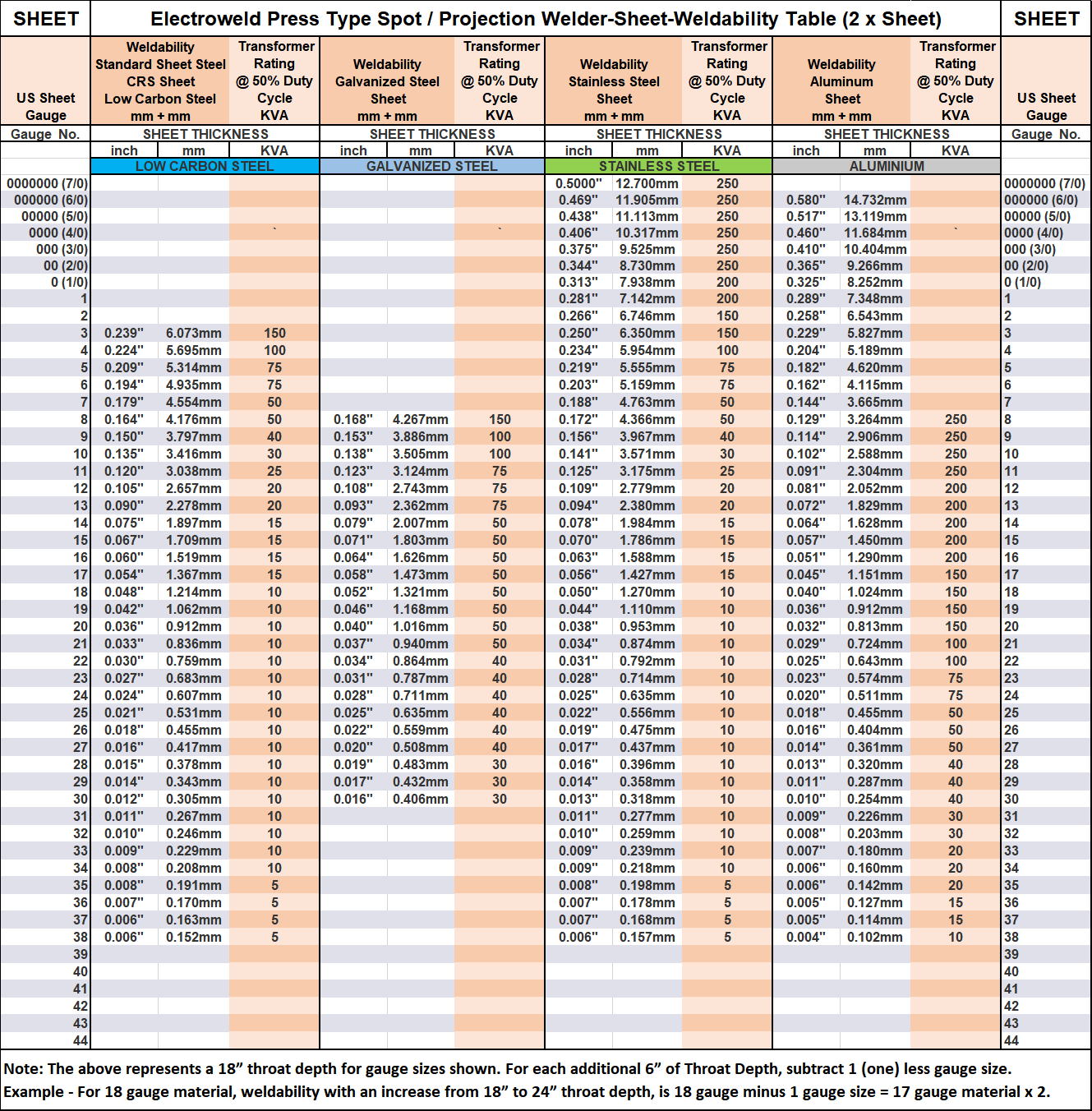

Note: For Bronze and Brass the Weldable thickness reduces and specs are available in table below

* Galvanized Steel Sheet Spot Welding- Galvanizing is a coating of zinc metal that is applied to the steel when it is manufactured, either in a hot dipped fashion or by electroplating. Zinc, when used as a galvanizing coating, protects steel from rust. Galvanized steel requires about 25% more horse power than non-galvanized steel. Weld time and/or weld power need to be increased to spot weld Galvanized steel. Select a higher KVA machine to account for the increased power requirement for spot welding Galvanized steel.

* Power Requirement is 220V AC 50/60Hz or 415V AC 50/60Hz(Price includes customization as per requirement before shipping)

**Spot Welders upto 30KVA can operate on either 2 Lines/Phases 220V (+10%/-10%) or 400V (+10%/-10%) 50/60Hz

***Spot Welders greater than 30KVA can only operate on 2 Lines/Phases 400V (+10%/-10%) 50/60Hz

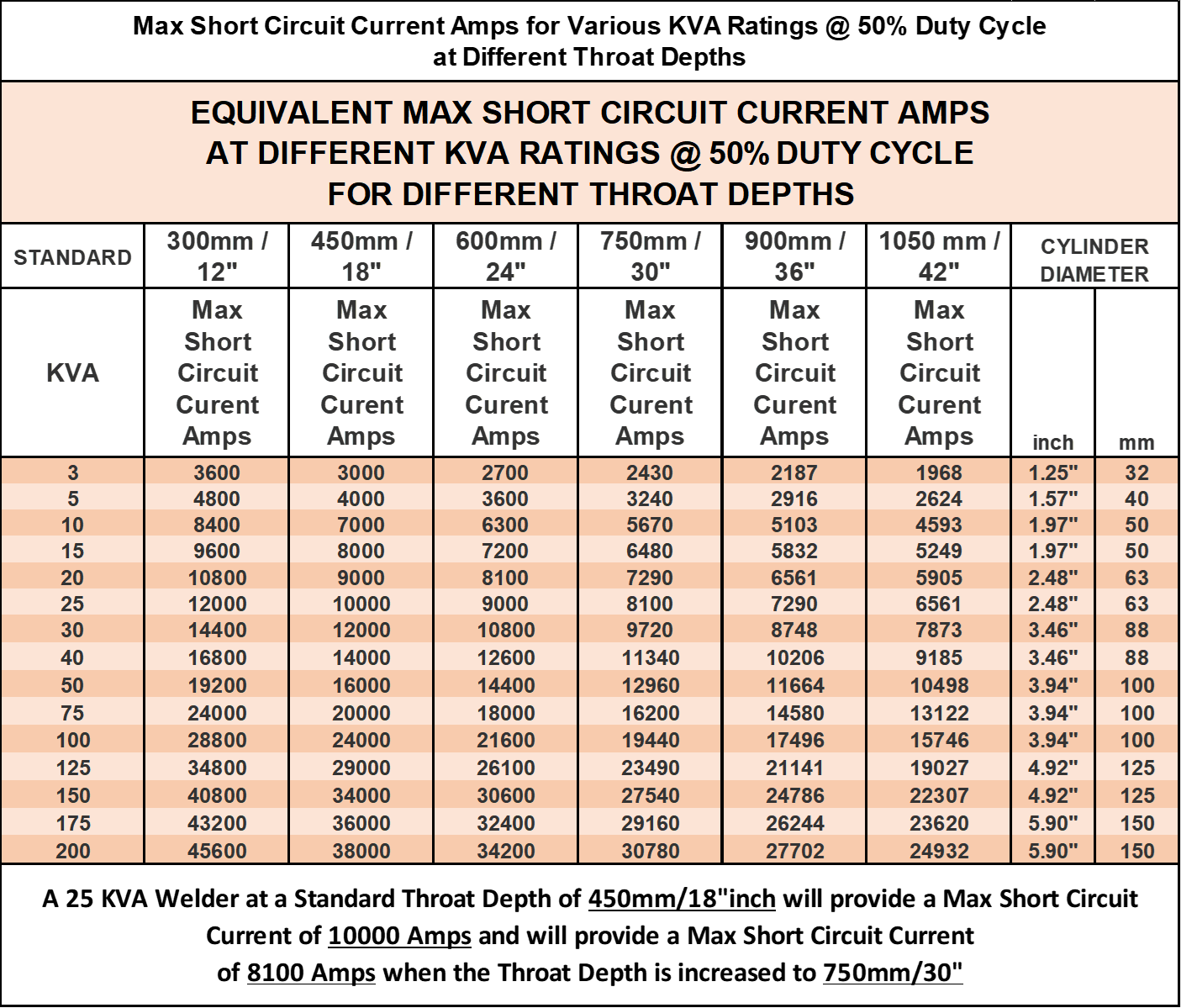

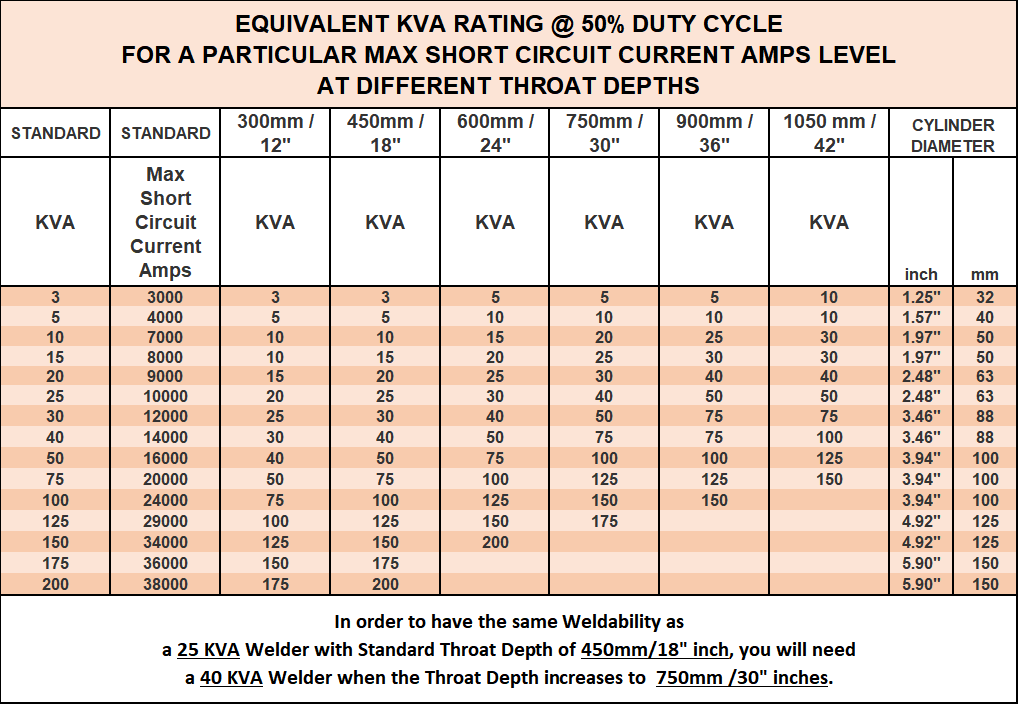

** Standard Throat Depth for Sheet Spot Welding or Cross Wire or Mesh Projection Spot Welding Application is 18" or 460mm (Customizable to 12” / 18” / 24” / 30” / 36” / 48” / 60” / 72” at an additional charge)

*** As Throat Depth increases, the Spot Welding capacity decreases for the same KVA Rated Spot Welder. Please contact us for any customization and confirmation of weldability based on your required throat depth.

***Standard Electroweld Forwel Constant Current Controller AK-54

***INCLUDED Standard Coolant Re-circulator Water Pump which is required for proper operation. Specs - 220V/415V 1/3 Phase

****Additional set of spares and consumables can be quoted to be added to the shipment as required

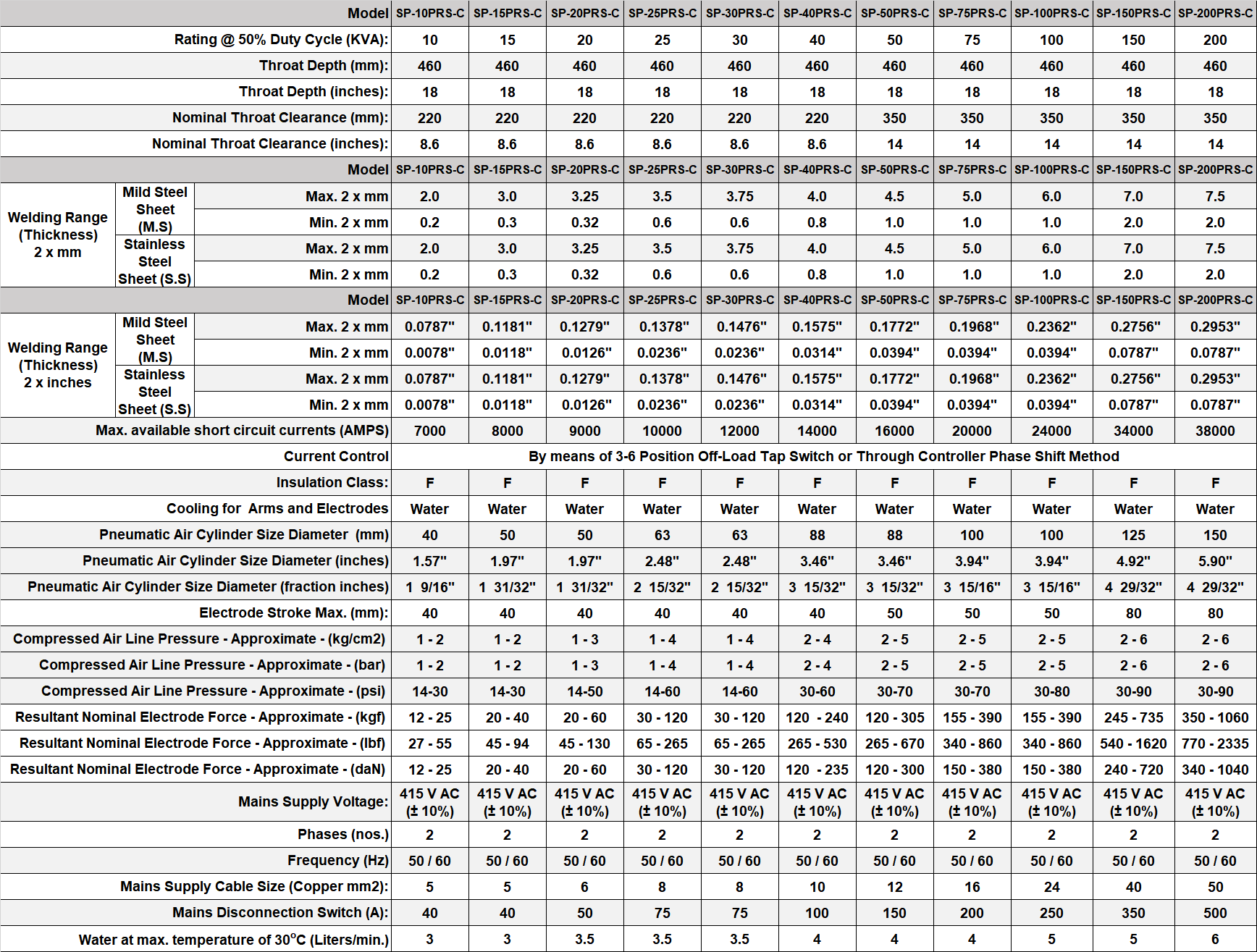

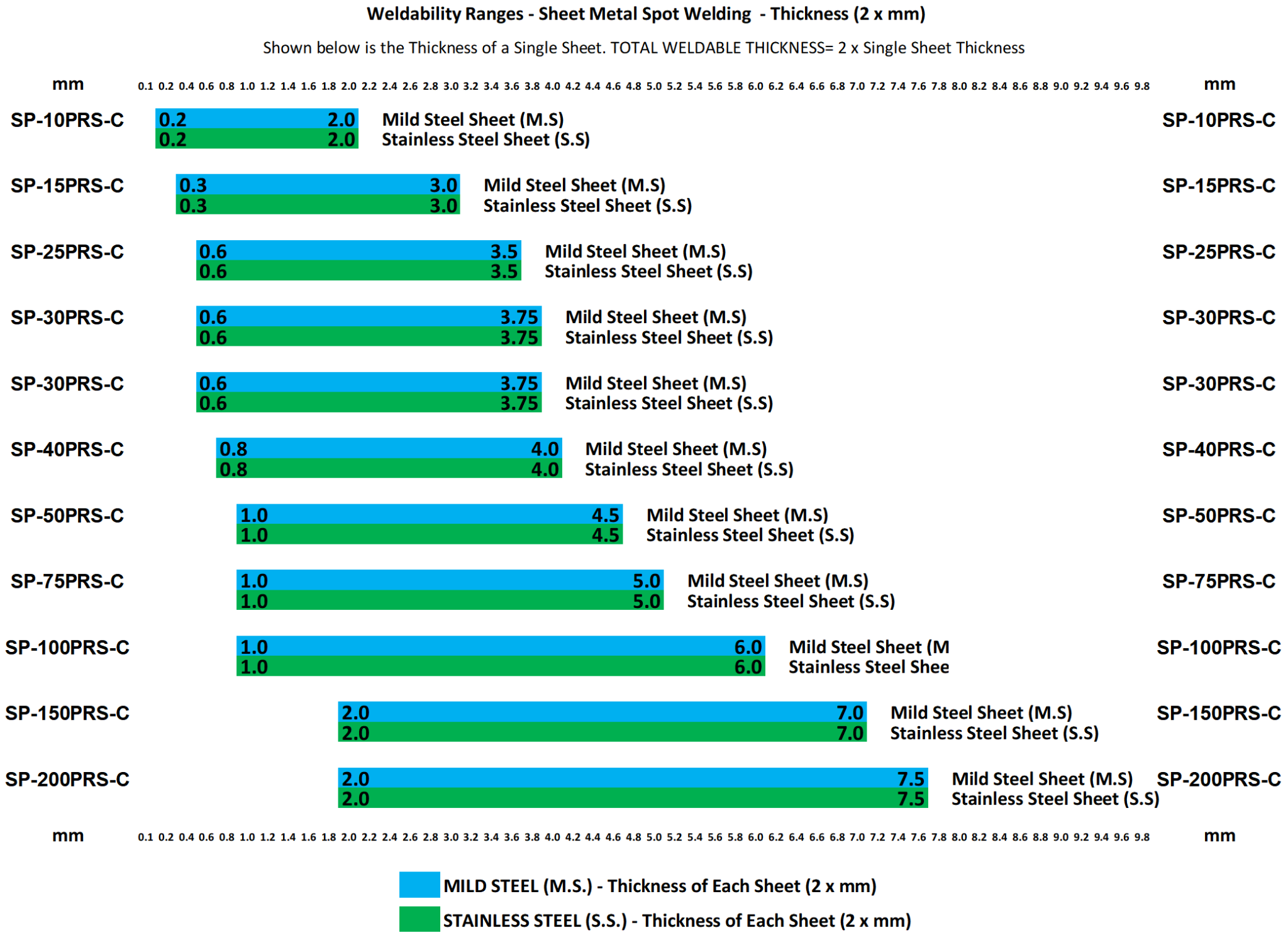

Specifications Table - Sheet Metal Spot Welding Application:

Note 1: ** Standard Throat Depth for Sheet Spot Welding or Cross Wire or Mesh Projection Spot Welding Application is 18" or 460mm (Customizable to 12” / 18” / 24” / 30” / 36” / 48” / 60” / 72” at an additional charge)

Note 2: *** As Throat Depth increases, the Spot Welding capacity decreases for the same KVA Rated Spot Welder. Please contact us for any customization and confirmation of weldability based on your required throat depth.

Note: * Maximum material welding thicknesses are always estimates. Variables such as Electrode Throat Depth, Electrode Throat Clearance, tooling, shunt or cable length, welder distance from primary, and other compounding variables can positively or negatively affect this number.

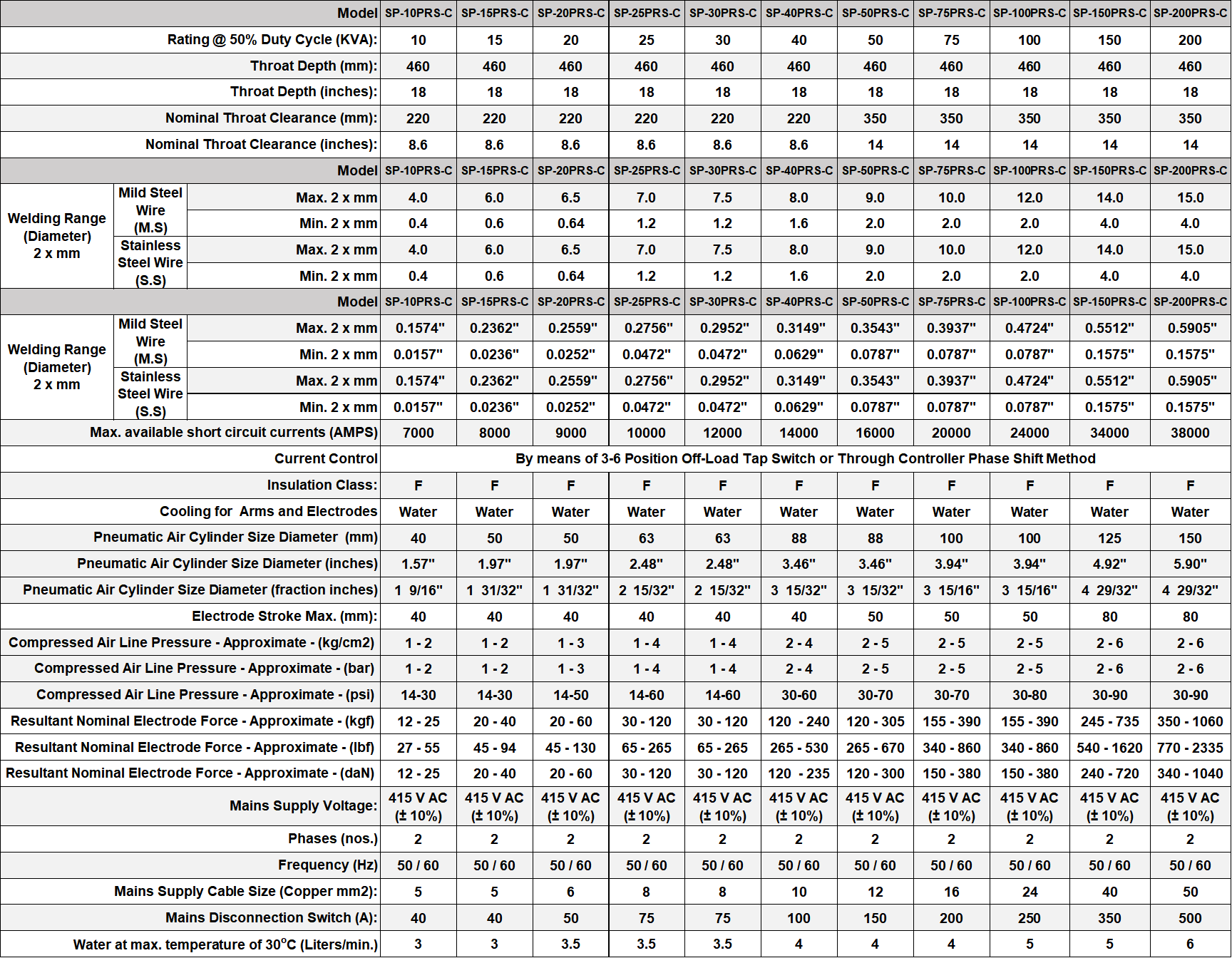

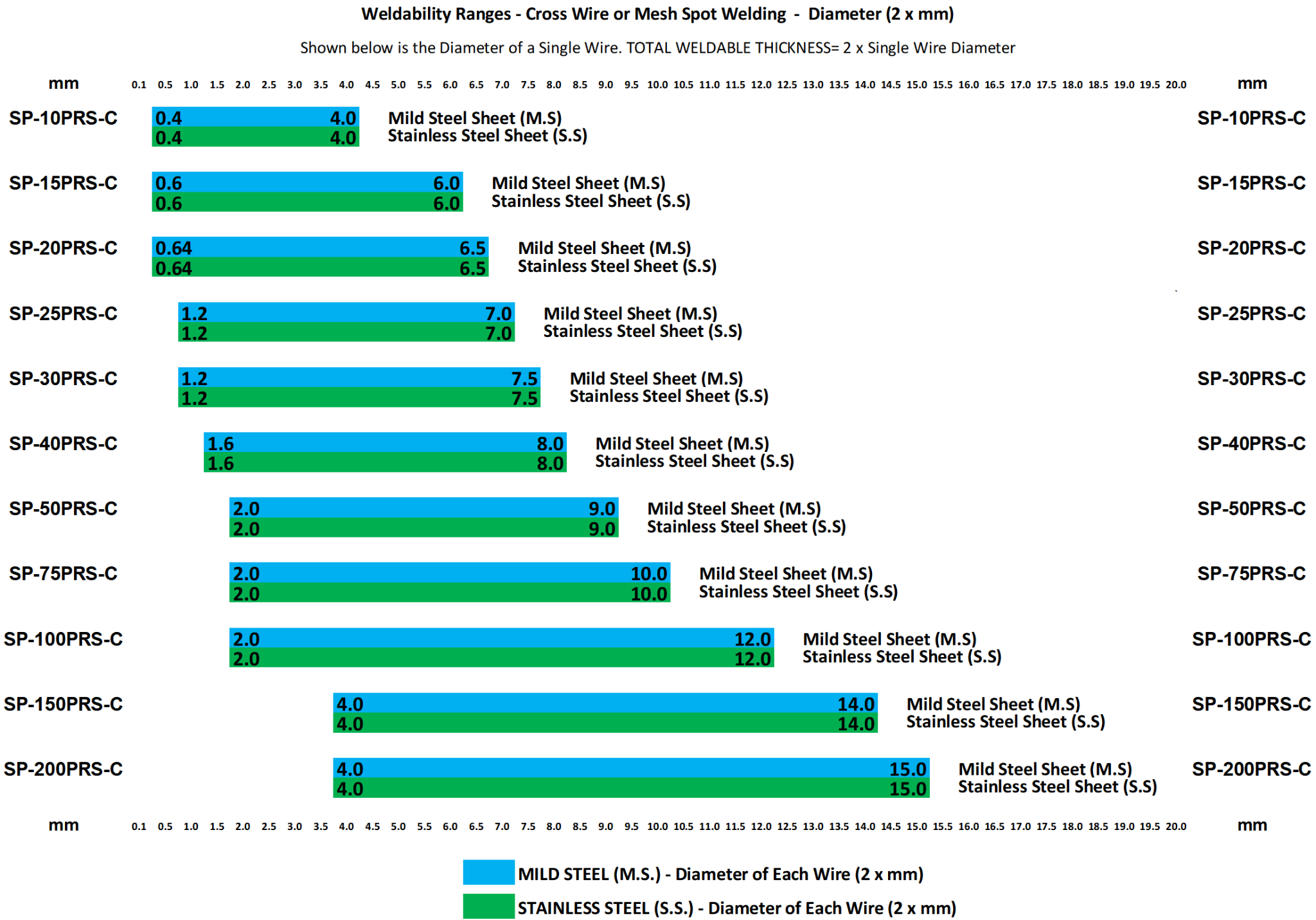

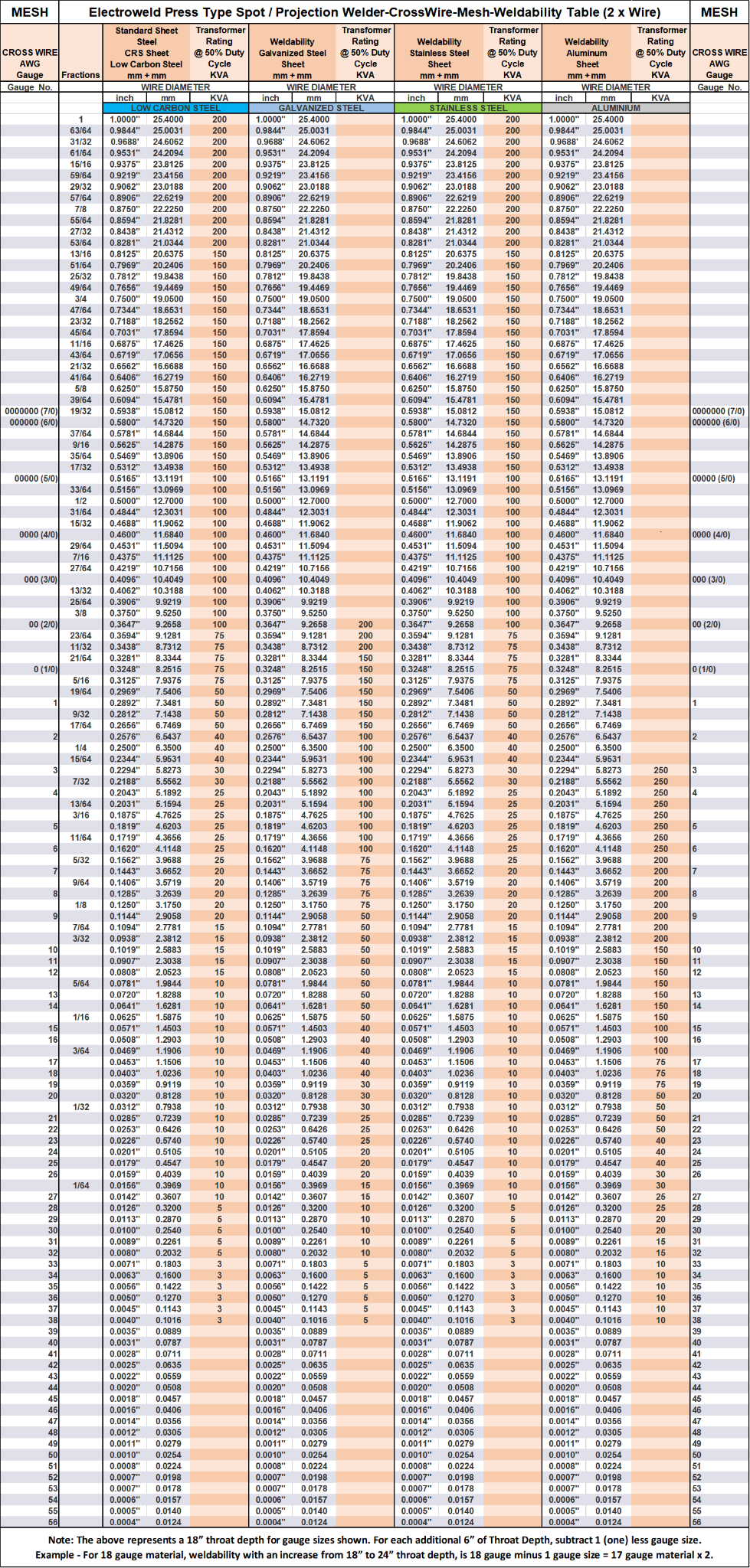

Specifications Table - Cross Wire or Mesh Spot Welding Application:

Note 1: ** Standard Throat Depth for Sheet Spot Welding or Cross Wire or Mesh Projection Spot Welding Application is 18" or 460mm (Customizable to 12” / 18” / 24” / 30” / 36” / 48” / 60” / 72” at an additional charge)

Note 2: *** As Throat Depth increases, the Spot Welding capacity decreases for the same KVA Rated Spot Welder. Please contact us for any customization and confirmation of weldability based on your required throat depth.

Note: * Maximum material welding thicknesses are always estimates. Variables such as Electrode Throat Depth, Electrode Throat Clearance, tooling, shunt or cable length, welder distance from primary, and other compounding variables can positively or negatively affect this number.

The weldability of your application can be checked with the Electroweld KVA-mm-SWG-AWG Mapping Table for MS/SS available HERE

The Electroweld Projection Spot Welder Weldability Table with SWG-mm-KVA Mapping is available HERE

The Electroweld Projection Spot Welder Weldability Table with AWG-mm-KVA Mapping is available HERE

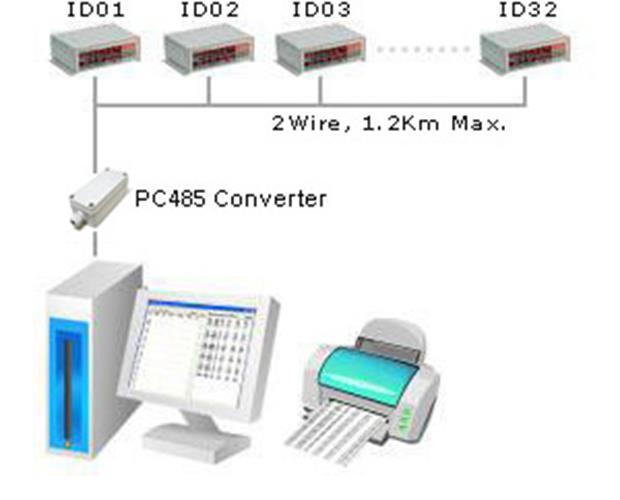

Electroweld Forwel Constant Current Controller AK-54V Networking

RS485 Network (Optional)

- by using welding data logger software (fcom_v2.3), welding data can be collected from each controller in real time and collected data can be stored in excel format on a PC (Personal Computer)

- one PC can be linked to maximum 32 units

- weld current data and scheduled data can be requested to each controller and can be seen & printed

- weld schedule can be changed from PC

- event monitoring for welding defects, time & weld current data can be checked easily and in real time

- opto-isolated RS485 converter (option) is installed in the controller

- PC can be connected to controller via 2 wire (RS-485) cable with max distance 1200 meters

Electroweld Forwel Constant Current Controller AK-54V Specifications Table